منتج

يحافظ نظام الإدارة الحرارية للبطارية على درجات حرارة حزمة بطارية السيارة الكهربائية ضمن النطاق الصحيح للحفاظ على نطاق القيادة الأطول وإطالة عمر البطارية. نحن نسميها أيضًا بطارية BTMS أو مبرد البطارية أو نظام تبريد حزمة البطارية.

شركة TKT Busthermo متخصصة في تطوير أنظمة الإدارة الحرارية لبطاريات الحافلات الكهربائية, بطاريات الشاحنات الكهربائية, بطاريات القوارب الكهربائية وبطاريات المعدات الثقيلة الكهربائية. بقدرة تبريد/تدفئة تتراوح بين 3KW-10KW, إنها تحافظ على درجة حرارة حزمة بطارية الطاقة في النطاق الأمثل عن طريق تبريد سائل التبريد وتسخين PTC. وهذا يسمح للسيارات الكهربائية بتحقيق مدى أطول وعمر خدمة أطول.

الآن المزيد والمزيد من القمة العالمية 500 يختار مصنعو المركبات نظام TKT BTMS, مثل بي واي دي, تاتا موتورز, تبديل التنقل, كاتربيلر وغيرها الكثير. أساسا بسببنا:

1. تتميز منتجات BTMS بجودة جيدة وقد اجتازت اختبار السوق 10 سنين.

2. التحكم الدقيق في درجة الحرارة (0.5درجه مئوية), خفيفة الوزن, إلخ..

3. سعر عادل ومغري.

4. بالإضافة إلى ذلك, هذا جزء قابل للتخصيص بدرجة كبيرة ويمكننا أن نجعله يتوافق تمامًا مع مواصفات العميل. تبريد, التدفئة, أبعاد, والمزيد يمكن تخصيصها جميعًا.

هناك أنواع عديدة من منتجات TKT. مرحبا بك في اتصل بنا للحصول على مشورة الخبراء أو بريد إلكتروني:md@tkt-hvac.com.

حسب الطلب: البعد / التبريد / التدفئة

سعة: تبريد 8-10 كيلو وات/ تدفئة 6-10 كيلو وات

تدفق: 45-75لتر/دقيقة

الجهد االكهربى: DC240V-DC750V

موديل المنتج: 10ر / 10الأسلحة الكيميائية لEB

وزن: 40كجم

البعد: 780*430*380مم (الطول*العرض*الارتفاع)

حسب الطلب: البعد / التبريد / التدفئة

سعة: تبريد 5-6 كيلو واط / التدفئة 3KW

تدفق: 45-75لتر/دقيقة

الجهد االكهربى: DC240V-DC750V

موديل المنتج: 5ر / 5الأسلحة الكيميائية لEB

وزن: 40كجم / 32كجم

البعد: 750*550*293مم / 618*350*392.5مم (الطول*العرض*الارتفاع)

حسب الطلب: البعد / التبريد / التدفئة

مُستَحسَن: تبريد 3-4 كيلو وات/ تدفئة 1-2 كيلو وات

تدفق: 45-75لتر/دقيقة

الجهد االكهربى: DC240V-DC750V

موديل المنتج: 3ر / 3الأسلحة الكيميائية لEB

وزن: 25كجم / 40كجم

البعد: 587*355*242مم / 447*310*583مم (الطول*العرض*الارتفاع)

حسب الطلب: البعد / التبريد / التدفئة

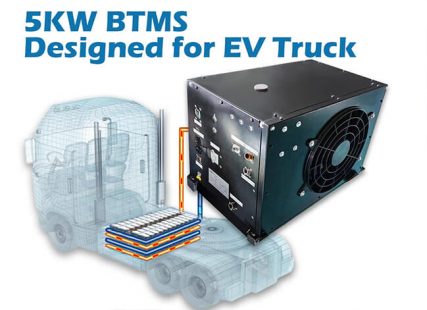

مُستَحسَن: تبريد 5 كيلو وات / تدفئة 3 كيلو وات

تدفق: 45-75لتر/دقيقة

الجهد االكهربى: DC240V-DC750V

موديل المنتج: 5الأسلحة الكيميائية لET

وزن: 32كجم

البعد: 618*350*392.5مم (الطول*العرض*الارتفاع)

حسب الطلب: البعد / التبريد / التدفئة

مُستَحسَن: Cooling 10KW/ Heating 6KW

تدفق: 45-75لتر/دقيقة

الجهد االكهربى: DC240V-DC750V

موديل المنتج: 10الأسلحة الكيميائية لEHE

البعد: 780*430*380مم (الطول*العرض*الارتفاع)

حسب الطلب: البعد / التبريد / التدفئة

مُستَحسَن: تبريد 5 كيلو وات / تدفئة 3 كيلو وات

تدفق: 45-75لتر/دقيقة

الجهد االكهربى: DC240V-DC750V

موديل المنتج: 5R لـ EHE

وزن: 40كجم

البعد: 750*550*293مم (الطول*العرض*الارتفاع)

حسب الطلب: البعد / التبريد / التدفئة

سريع OEM/تصميم حسب الطلب (1 شهر)

التحكم الدقيق في درجة الحرارة (0.5 أنت. سي)

يمكن التحكم لتجنب التشغيل الخاطئ لتلف حزمة البطارية

حسب الطلب: البعد / التبريد / التدفئة

OEM سريع/تصميم مخصص (1 شهر)

التكنولوجيا المبتكرة: نقوم بدمج أنظمة تكييف الهواء للحافلة الكهربائية وتبريد البطارية لتشكيل نظام إدارة حراري أكثر شمولاً للمركبات الكهربائية.

✲ سعة تبريد مكيف الهواء في الحافلة الإلكترونية: 42كيلوواط / 143ك وحدة حرارية بريطانية

✲ سعة التبريد BCS: 8كيلوواط (التدفئة اختيارية)

✲ التطبيق: حافلة كهربائية نقية

✲ المزايا: تحسين الكفأة, احفظ المسافه, إصلاح أقل, حفظ التكاليف

✲ مخصصة: البعد / التبريد / التدفئة الخ.

✲ قمة العالم 500 بي واي دي/ تاتا المورد

✲ انتهى 200,000 الوحدات العاملة في جميع أنحاء العالم

✲ 10 سنوات من الخبرة في R&د والتصميم

✲ الشهادات: ايزو 9001, فرقة العمل المشتركة بين الوكالات 16949, إلخ.

طلب: نظام إدارة البطارية الحرارية للحافلات / شاحنة / المعدات الثقيلة / قارب الخ.

ل 10 سنين, قامت TKT بتصميم وتصنيع أنظمة تبريد سائلة للبطارية وفقًا لاحتياجات عملاء OEM المختلفين. مثل شركة BYD الصينية, حافلة يوتونغ, حافلة كينغ لونغ, إلخ. والأسواق الخارجية مثل شركة تاتا موتورز الهندية, دايو الكورية الجنوبية, وSwitch Mobility في المملكة المتحدة, إلخ. نظام الإدارة الحرارية للبطارية TKT (BTMS) يوفر قدرات تبريد وتدفئة تتراوح من 3 إلى 10 كيلو وات وفقًا لمتطلبات العملاء, ويمكنه تلبية متطلبات المركبات التجارية المختلفة حتى لو وصلت درجة الحرارة المحيطة إلى 60 درجة مئوية أو -20 درجة مئوية. تقوم TKT أيضًا بتصنيع مبرد البطارية المثبت على السقف, مبرد البطارية المثبت على الجانب ومبرد البطارية المثبت على الهيكل وفقًا لمتطلبات العملاء المختلفين. أصبحت TKT HVAC هي القمة 3 مصنعي نظام الإدارة الحرارية للبطارية وموردي BTMS في الصين.

“دراسة حالة الإدارة الحرارية لبطارية السيارة الكهربائية - قصة مخصصة للثروة 500” انقر للقراءة (موصى به للغاية)

“حظ 500 مشروع نظام الإدارة الحرارية لبطارية شاحنة TATA” انقر للقراءة

“تركز الإدارة الحرارية للبطارية على الشاحنة & الحافلة إلخ. – حلول متقدمة ناضجة” انقر للقراءة (موصى به للغاية)

“حلول تخصيص الإدارة الحرارية للبطارية واتجاهات التخصيص الشائعة” انقر للقراءة

نظام الإدارة الحرارية للبطارية (BTMS) هو نظام للتحكم في درجة الحرارة ذو حلقة مغلقة يتكون من وسط موصل للحرارة, وحدة القياس والتحكم, ومعدات التحكم في درجة الحرارة. فهو يجعل بطارية الطاقة تعمل ضمن نطاق درجة الحرارة المناسب للحفاظ على أفضل حالة استخدام لها لضمان أداء وعمر نظام البطارية.

تعتبر بطارية الطاقة المصدر الوحيد للطاقة للسيارات الكهربائية ومؤشر مهم يؤثر على أداء المركبات الكهربائية. ستصاحبها حرارة معينة أثناء عملية الشحن والتفريغ, مما سيؤدي إلى ارتفاع درجة الحرارة, وسوف تؤثر الزيادة في درجة الحرارة على العديد من خصائص عمل البطارية, مثل المقاومة الداخلية, الجهد االكهربى, شركة نفط الجنوب, القدرة المتاحة, كفاءة الشحن والتفريغ, وعمر البطارية.

ستؤثر مشكلة التأثيرات الحرارية لبطارية الطاقة على أداء السيارة ودورة حياتها. لذلك, تعد الإدارة الحرارية للبطارية أمرًا مهمًا جدًا لأداء البطارية وعمرها والمسافة المقطوعة بالسيارة.

في الوقت الحالي, وهي مقسمة بشكل رئيسي إلى تبريد الهواء, التبريد السائل, تبريد المواد المتغيرة الطور والتبريد بالغمر. لنظام تبريد بطارية EV, التبريد السائل هو الحل الأكثر شيوعًا واستقرارًا.

تبريد سائل البطارية: تقوم البطارية بتبادل الحرارة مع سائل التبريد من خلال لوحة التبريد. يتم إرسال المبرد المبرد أو الساخن إلى المبادل الحراري بواسطة مضخة ماء, ويتم إجراء التبادل الحراري والتحويل بداخله, وبالتالي تشكيل نظام تبريد سائل مستمر ومستقر للبطارية. دورة فاضلة.

تبريد هواء البطارية: يستخدم بشكل أساسي مبدأ عمل الحمل الحراري للهواء لتدوير الهواء في حجرة البطارية. الهواء المتداول يزيل الحرارة من البطارية, وبالتالي خفض درجة حرارة البطارية. العيب هو أن كفاءة التبريد منخفضة نسبيا, خاصة في البيئات ذات درجات الحرارة المرتفعة.

مادة تغيير طور البطارية (بي سي إم) تبريد: تُستخدم مواد PCM بشكل أساسي للتحول بين الحالة الصلبة والسائلة عند درجات حرارة محيطة محددة, وبالتالي تحقيق وظائف تبديد الحرارة والتدفئة للبطارية. تتمثل العيوب في كفاءة التبريد المنخفضة نسبيًا والحاجة إلى الاستبدال المنتظم للمواد المتغيرة الطور.

تبريد غمر البطارية: عن طريق وضع البطارية مباشرة في مبرد خاص, تُستخدم تأثيرات الحمل الحراري والتوصيل للسائل لنقل الحرارة الناتجة عن البطارية إلى سائل التبريد بسرعة, وبالتالي تحقيق تأثير التبريد للبطارية. العيوب هي متطلبات أعلى لسائل التبريد وارتفاع تكاليف الصيانة اللاحقة.

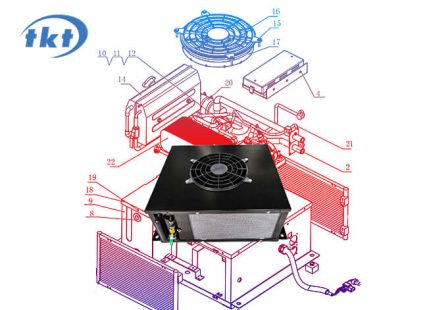

يتكون نظام التبريد السائل للبطارية من ضاغط, مكثف, صمام توسع, مبادل حراري لوحة, مضخة المياه الإلكترونية, سخان سائل PTC, خزان التوسع, والتحكم الكهربائي. عندما تحتاج البطارية إلى التبريد للتشغيل, تقوم البطارية بتبادل الحرارة مع سائل التبريد من خلال لوحة التبريد, ويتم إرسال المبرد الساخن إلى المبادل الحراري بواسطة مضخة المياه الإلكترونية. يتم إدخال سائل التبريد إلى جانب واحد من المبادل الحراري ويتم إدخال سائل التبريد إلى الجانب الآخر. يتبادل الاثنان الحرارة في المبادل الحراري, بحيث يتم أخذ الحرارة بعيدا عن طريق المبرد. يتدفق سائل التبريد البارد من المبادل الحراري ثم يتدفق إلى البطارية. يشكل النظام دورة; عندما تكون البطارية في درجة حرارة منخفضة وتحتاج إلى التسخين, يتم إغلاق دائرة التبريد وتشغيل سخان السائل PTC. يتم تسخين سائل التبريد وإرساله إلى البطارية, ويتم تسخين البطارية من خلال لوحة التبريد. تتحكم الإدارة الحرارية للبطارية في درجة الحرارة الداخلية للبطارية عن طريق التحكم في تشغيل وإيقاف دائرة التبريد وسخان السائل PTC.

ببساطة, BMS هو نظام لإدارة البطارية, والذي يتضمن نطاقًا أوسع. BTMS هو نظام الإدارة الحرارية للبطارية وهو جزء من BMS. يتطلب التشغيل الآلي لـ BTMS تعليمات من BMS. ويمكن فهمها على أنها العلاقة بين الدماغ والأطراف.

بطارية مبردة بالماء, حزمة بطارية سائلة مبردة, الإدارة الحرارية للبطاريات, نظام التبريد لحزمة البطارية, وحدة تبريد البطارية, نظام الإدارة الحرارية للبطارية Btms, نظام تبريد بطارية الليثيوم, بطارية ليثيوم أيون التبريد, الإدارة الحرارية لبطارية ليثيوم أيون, نظام إدارة درجة حرارة البطارية, تبريد بطارية الليثيوم, نظام الإدارة الحرارية للبطارية للسيارات الكهربائية, الإدارة الحرارية للبطارية, نظام تبريد البطارية في السيارة الكهربائية, أنظمة تبريد بطارية EV, نظام الإدارة الحرارية لبطارية السيارة, نظام تبريد بطارية السيارة الكهربائية, نظام تبريد بطارية السيارة الكهربائية, نظام تبريد بطارية الجهد العالي, الإدارة الحرارية للبطارية, نظام الإدارة الحرارية للبطارية EV, الإدارة الحرارية لحزمة البطارية, بطارية تبريد سائلة.