✲ مخصصة: البعد / التبريد / التدفئة الخ.

✲ قمة العالم 500 بي واي دي/ تاتا المورد

✲ انتهى 200,000 الوحدات العاملة في جميع أنحاء العالم

✲ 10 سنوات من الخبرة في R&د والتصميم

✲ الشهادات: ايزو 9001, فرقة العمل المشتركة بين الوكالات 16949, إلخ.

طلب: نظام إدارة البطارية الحرارية للحافلات / شاحنة / المعدات الثقيلة / قارب الخ.

درجة حرارة التشغيل المثالية لبطارية السيارة الكهربائية هي 20 درجة إلى 45 درجة. إذا تم تجاوز درجة الحرارة هذه, سينخفض نطاق القيادة وعمر البطارية بشكل كبير. ما هو أكثر من ذلك, كما أنها قد تؤثر على المعدات المحيطة وتسبب عواقب الاحتراق والانفجار. إذا كانت البطارية أقل من درجة الحرارة هذه, سيصبح نشاط التفاعل الكهروكيميائي ضعيفًا وسيقل أداء البطارية بشكل كبير.

نظام الإدارة الحرارية للبطارية هو نظام مصمم خصيصًا لتبريد بطاريات الطاقة. إنه عنصر لا غنى عنه في المركبات الكهربائية التجارية. يعتمد نظام تبريد بطارية TKT التبريد السائل وPTC للتدفئة, والتي يمكن أن تزيل بشكل ثابت كمية كبيرة من الحرارة الناتجة عن البطارية. هذه هي طريقة تبريد البطارية الأكثر استخدامًا للحافلات الكهربائية, الشاحنات الكهربائية, المعدات الثقيلة الكهربائية, والقوارب الكهربائية.

انقر لمعرفة المزيد عن هذا المبدأ

يحتوي نظام الإدارة الحرارية لبطارية TKT على مجموعة واسعة من الحلول. تتراوح قدرة التبريد من 3 إلى 10 كيلو واط، كما أن مواضع التثبيت مثبتة في الأعلى ومثبتة على الجانب. هناك أيضا الأحدث نظام BTMS المتكامل لتكييف هواء الحافلات, وهو حل متكامل للحافلات الكهربائية. تدعم TKT أيضًا خدمة تخصيص OEM. يمكننا حل 99% من مختلف العملاء’ الاحتياجات.

يعمل تلقائيًا للحفاظ على استقرار درجة حرارة البطارية

▲أكثر من 10 سنوات من إثبات السوق, زيادة 200,000 الوحدات العاملة في جميع أنحاء العالم, مع الجودة والأداء المعترف بها على نطاق واسع في جميع أنحاء العالم.

▲تصميم حاصل على براءة اختراع لتوفير تبريد/تدفئة أعلى بوزن أقل;

▲تدفق أكبر لسائل التبريد للحفاظ على درجة حرارة البطارية في أقصر درجة حرارة;

▲يمكن التحكم لتجنب التشغيل الخاطئ لتلف حزمة البطارية (يعمل تلقائيًا للحفاظ على استقرار درجة حرارة البطارية);

▲اعتماد الأجزاء الكهربائية IP67, مثل الضاغط الكهربائي, مضخة مياه, موصلات إلخ;

▲تصميم سريع OEM/حسب الطلب (1 شهر);

▲تحكم دقيق في درجة الحرارة (0.5 أنت. سي);

على مدى 10 سنين, لقد تطورت TKT HVAC بسرعة وأصبحت الأفضل 3 الشركات المصنعة لنظام الإدارة الحرارية للبطارية في الصين. مع تجربة تصنيع المعدات الأصلية الغنية, لقد تعاونا مع العديد من الشركات المصنعة للسيارات المشهورة عالميًا. مثل بي واي دي, دراجات نارية تاتا, تبديل التنقل, دايو, إلخ. تشمل المشاريع التعاونية مجموعة متنوعة من نظام الإدارة الحرارية لبطاريات الحافلات الكهربائية, نظام الإدارة الحرارية لبطارية الشاحنة الخفيفة, نظام الإدارة الحرارية لبطارية الشاحنات الثقيلة, إلخ.

“دراسة حالة الإدارة الحرارية لبطارية السيارة الكهربائية - قصة مخصصة للثروة 500” انقر للقراءة (موصى به للغاية)

اختبار السيارة الحقيقي, عملية مستقرة (انقر على الصورة لتكبيرها)

مرحبا بكم في الاتصال بنا للحصول على المشورة النموذجية المهنية. فضلاً عن ذلك, TKT يوفر خدمات تخصيص OEM, ومصنعي المركبات مدعوون للتشاور.

| يدعم حسب الطلب خدمات |

|

|

| سعة | تبريد: 8-10كيلوواط التدفئة: 6-10كيلوواط (خياري) |

تبريد: 5-6كيلوواط التدفئة: 3كيلوواط (خياري) |

| طلب | 11-12M الحافلة الكهربائية BTMS (DC240V-DC750V) |

8-10M الحافلة الكهربائية BTMS (DC240V-DC750V) |

| منتج نموذج |

10R/10CW للحافلات الإلكترونية عرض الصفحة 10R/10CW |

5R/5CW للحافلات الإلكترونية عرض الصفحة 5R/5CW |

| يدعم حسب الطلب خدمات |

|

|

| سعة | تبريد: 3-4كيلوواط التدفئة: 1-2كيلوواط (خياري) |

تبريد: 5-6كيلوواط التدفئة: 3كيلوواط (خياري) |

| طلب | 6-7M الحافلة الكهربائية BTMS (DC240V-DC750V) |

شاحنة كهربائية BTMS (DC240V-DC750V) |

| منتج نموذج |

3R/3CW لـ EBus عرض الصفحة 3R/3CW |

5الأسلحة الكيميائية لـ Etruck عرض الصفحة 5CW |

| يدعم حسب الطلب خدمات |

|

|

| سعة | تبريد: 3-4كيلوواط التدفئة: 1-2كيلوواط (خياري) |

تبريد BTMS: 8كيلوواط تبريد مكيف الهواء للحافلة: 143ك وحدة حرارية بريطانية |

| طلب | المعدات الثقيلة الإلكترونية BTMS (DC240V-DC750V) |

مكيف الهواء للحافلة الإلكترونية + BTMS (DC240V-DC750V) |

| منتج نموذج |

3R لـ EHE عرض الصفحة 3ر |

عرض النظام المتكامل للصفحة |

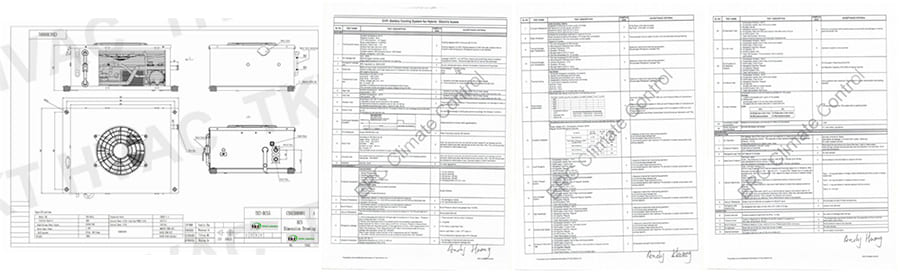

اتصل بنا للحصول على صور عالية الدقة

1. نوع البطارية ومواصفاتها: تحتوي سيناريوهات تطبيق البطارية المختلفة على متطلبات مختلفة لنظام الإدارة الحرارية للبطارية. على سبيل المثال, إذا كانت بطارية طاقة ويتم تطبيقها على حافلة كهربائية, يتراوح جهد البطارية عادة بين 280 فولت-750 فولت. عندما تعمل الحافلة الكهربائية, تنتج البطارية الكثير من الحرارة, الأمر الذي يتطلب نظام تبريد سائل للبطارية.

2. مساحة احتياطية EV: عندما يقوم مصنعو السيارات المختلفون بتصميم مركبات جديدة, تم تخطيط مساحة التصميم لكل جزء. على سبيل المثال, لأن الشاحنات الكهربائية بها صناديق, نوصي عادةً بتصميم نظام الإدارة الحرارية لبطارية الشاحنة (BTMS) على الجزء الخارجي من الشاحنة واعتماد حل التثبيت المثبت على الجانب. وتتمثل ميزة ذلك في أنه يفضي إلى إطلاق أداء تبديد الحرارة وكفاءة تبريد البطارية عالية. بالطبع, لدينا أيضًا حلول تبريد بطاريات الشاحنات الأخرى التي يمكن حلها 95% احتياجات تبريد بطارية الشاحنة. على سبيل المثال آخر, المساحة الإجمالية للآلات الثقيلة الكهربائية صغيرة, لذلك هناك متطلبات صارمة بشأن حجم نظام الإدارة الحرارية للبطارية. لدينا حلول تبريد البطارية المقسمة ونقدم أيضًا خدمات مخصصة, حتى نتمكن من حل احتياجات نظام الإدارة الحرارية للبطارية بأحجام مختلفة بشكل مثالي.

3. الجودة والموثوقية: نظام الإدارة الحرارية للبطارية (BTMS) مهم جدًا للسيارات الكهربائية. لا يمكنها ضمان سلامة السيارة فحسب، بل يمكنها أيضًا تقليل تكاليف تشغيل السيارة. يمكن لنظام التبريد عالي الجودة أن يحسن بشكل كبير عمر البطارية ونطاق السيارة, وبالتالي تقليل تكاليف استبدال البطارية وتكاليف شحن السيارة. لذلك من المهم جدًا اختيار نظام جيد لإدارة حرارة البطارية. تم توفير منتجات TKT BTMS لشركة Fortune 500 شركات, مرت عمليات التفتيش الصارمة, وكانت قيد التشغيل الفعلي للمركبة لأكثر من 5 سنين. الممارسة فقط هي التي يمكنها معرفة ما إذا كان المنتج جيدًا أم لا. خمس سنوات من التشغيل المستقر هي أفضل دليل. تتمتع TKT بخبرة غنية في التعاون مع الشركات المصنعة للمركبات OEM, مثل مشروع بي واي دي, مشروع تاتا موتورز, مشروع تبديل التنقل, إلخ.

لفائف المكثف, مروحة المكثف, خزان المياه, مضخة مياه, مبادل حراري, ضاغط كهربائي, لوحة التحكم, يمكن الوحدة, صمام توسع, إلخ.

يقوم نظام المكثف بتبريد سائل التبريد وتقوم مضخة الماء بتشغيل سائل التبريد من خلال نظام BTMS ونظام هيكل البطارية لتحرير الحرارة الناتجة عن حزمة البطارية.

ينقسم نظام الإدارة الحرارية للبطارية بشكل أساسي إلى تبريد هواء البطارية, التبريد السائل للبطارية, تبريد المواد المتغيرة الطور, وتبريد غمر البطارية. يجب تحديد طرق تبريد مختلفة بناءً على حكم السيناريو. للسيارات الكهربائية التجارية, لأن سعة بطارية السيارات الكهربائية كبيرة نسبياً, كلها بطاريات طاقة عالية الجهد, لذلك يطلقون الكثير من الحرارة. الآن البرنامج الأكثر فعالية من حيث التكلفة واستقرارًا هو التبريد السائل للبطارية.

تتمثل وظيفة نظام الإدارة الحرارية للبطارية في ضبط درجة حرارة البطارية في الوقت الفعلي والحفاظ على تشغيل البطارية ضمن نطاق درجة الحرارة الأمثل لضمان أداء البطارية, الحياة والسلامة. يتحدث بشكل رئيسي, وهي مقسمة إلى الحالات التالية.

1. منع ارتفاع درجة الحرارة: عندما تكون درجة حرارة البطارية مرتفعة جدًا, سوف يتأثر أداء البطارية وقد يحدث عطل. يمكن لنظام الإدارة الحرارية للبطارية تقليل درجة حرارة البطارية في الوقت المناسب من خلال تبديد الحرارة وطرق أخرى لمنع ارتفاع درجة حرارة البطارية.

2. منع التبريد الزائد: في البيئات ذات درجات الحرارة المنخفضة, سوف يتأثر أداء البطارية أيضًا وقد يفشل في العمل بشكل صحيح. يمكن لنظام الإدارة الحرارية للبطارية أن يزيد درجة حرارة البطارية على الفور من خلال التسخين وطرق أخرى لمنع البطارية من التبريد الزائد.

3. الحفاظ على ثبات درجة حرارة البطارية: أثناء قيادة السيارة, سوف تستمر درجة حرارة البطارية في التغير. إذا كان تقلب درجات الحرارة كبيرًا جدًا, سيكون له تأثير سلبي على أداء البطارية. يمكن لنظام الإدارة الحرارية للبطارية أن يحافظ على استقرار درجة حرارة البطارية عن طريق التحكم في تدفق سائل التبريد وطرق أخرى.

4. تحسين عمر البطارية: من خلال التحكم في درجة حرارة البطارية ضمن النطاق الأمثل, يمكن تمديد عمر البطارية. تقليل عدد البدائل وتقليل تكاليف الصيانة.

تعد تقنية تبريد البطارية أكثر تطلبًا لتصميم الحافلات الكهربائية والشاحنات الكهربائية, الذي تعمل عليه TKT منذ ذلك الحين 2012.

الحل الأكثر فعالية لتحسين نطاق القيادة دون زيادة عدد البطاريات هو نظام إدارة حراري للبطارية مخصص.

حالة الإدارة الحرارية لبطارية السيارة الكهربائية – مخصصة للثروة 500. يحتوي نظام BTMS الخاص بـ TKT على 10 سنوات من الخبرة في التصميم.