This article will introduce in detail some information about bus air conditioning unit. Include the following contents respectively:

1 What type of AC is used in buses?

2 Installation steps of bus air conditioning unit

3 What is bus air conditioning unit?

4 How does the HVAC system work on a bus?

5 What does an AC bus do?

I'll start with the bus model. First of all, the most common diesel bus. It usually uses an engine-driven bus air conditioning unit. This type of air conditioning unit has a high cooling capacity and is cost-effective. The disadvantage is that it cannot use when parked. If you need to use it when parking, we recommend choosing Sub Engine Bus Air Conditioning (but relatively expensive).

Let me add another special case - mini bus. This kind of bus can choose 1 or 2 12v/24v mini bus air conditioning unit. This solution has a relatively low cooling capacity and is suitable for areas and countries that are not very hot.

Followed by the new electric buses. This kind of bus uses high-voltage power battery as energy source. They have high battery capacity and can be used for electric bus air conditioning. Whether it is cooling capacity or parking use, it can easily meet your needs.

TKT HVAC busthermo is one of the top 3 bus air conditioner manufacturers in China. Founded in 1998, it has rich OEM customization experience and production experience. We have a variety of solutions that are sure to solve your coach cooling problems. Welcome to leave a message to communicate.

1. Opening: Check that the bus roof opening should be consistent with the opening size of the air conditioner.

2. Cleaning: Clean the car roof to ensure it is clean and tidy.

3. Sealing: Apply sealing insulation sponge around the roof air outlet and return air outlet, and ensure sealing.

4. Fixing: Find the corresponding positions of all bolts and shock-absorbing rubber pads, and use sealant to fix them.

5. Installation: Hoist the bus air conditioning unit. After finding the installation location, use the corresponding mounting holes and bolts to secure it firmly. Then apply sealant again to strengthen the fixation.

6. Interior: Check the interior of the bus to see if the sealing insulation sponges on the air outlet and return air outlet are compacted and sealed. Then apply sealant evenly, with a thickness of not less than 3MM. To strengthen fixation and sealing.

7. Cleaning: After all work is completed, clean the inside of the bus air conditioning unit and install the top cover correctly on the roof unit.

1. The evaporation chamber of the air conditioner has drainage holes. After connecting the drainage hose, fix the pipe in the air ducts on both sides of the roof and lead it to the outside of the car. During the installation process, attention should be paid to ensuring that the water pipes are not compressed and prevented from coming into contact with sharp objects.

2. To install the refrigeration pipeline, first slowly loosen the blockage at the joint between the evaporator and the condenser to allow the precharged dry nitrogen to overflow. Then connect the refrigeration pipeline to the evaporator and condenser correspondingly. Apply refrigeration oil to the sealing ring, spreading it evenly to ensure good contact.

Fix the compressor on the bus chassis, tighten the bolts, adjust the shock absorber spring, and fix the compressor clutch on the compressor bracket. Then connect the drive belt of the compressor to the bus engine, making sure it is tight. Other pipeline parts are fixed with clamps and must be kept away from heat sources and sharp objects to ensure heat dissipation and longevity as much as possible.

1. Pour in nitrogen to maintain pressure to check the tightness of the refrigeration system, and finally fill it with refrigerant.

2. Check all connections to make sure they are installed correctly and tight.

3. Start the air conditioning system and check its operation. Listen carefully for abnormal noise and check for abnormal vibration.

4. After running the system for a while, check the pressure and temperature again to make sure they are within the normal range.

5. Finally, perform a thorough cleaning and inspection to ensure that all work has been completed and no parts have been missed.

Bus air conditioning unit is the air conditioner installed on the bus. Its principle is similar to that of home air conditioners, but bus air conditioning also need to consider the driving status and bumps of the vehicle. Therefore, it needs to adopt more stable and reliable refrigeration technology and materials. It is very important for passenger comfort experience.

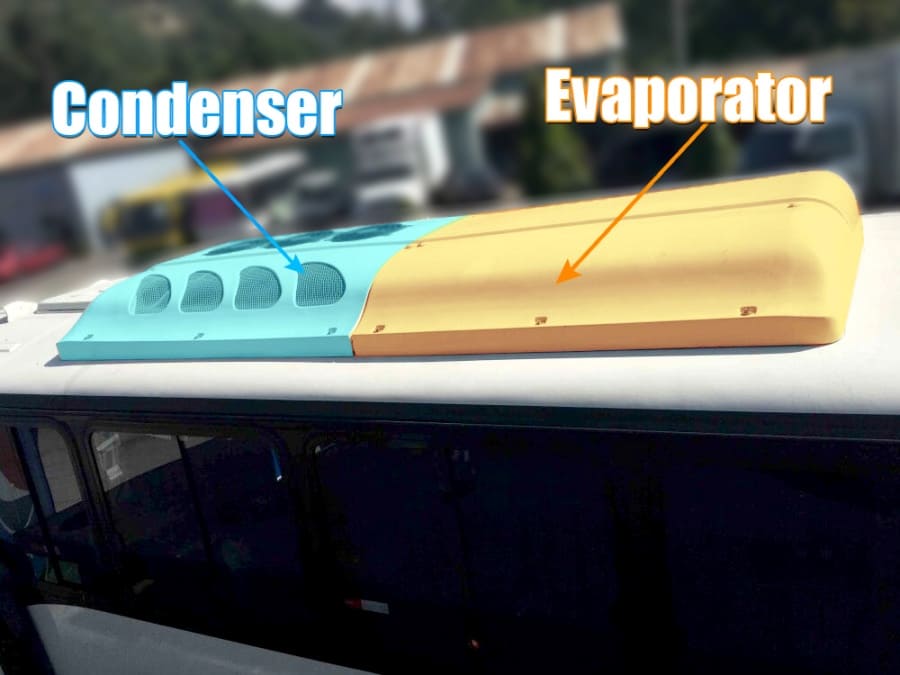

Bus air conditioner is mainly composed of compressor, condenser, evaporator, piping system and electronic control system. Usually the condenser and evaporator are installed on the roof of the bus. The liquid reservoir, dry filter and expansion valve are installed inside the evaporator. The air conditioner controller is installed on the dashboard.

The condenser is a heat exchange device that condenses the high-pressure and high-temperature refrigerant gas discharged from the compressor into a liquid state after releasing heat through it.

Specifically, in the condenser it is the refrigerant that transfers heat to the surrounding ambient air. The refrigerant flows in the tube. During the heat release process, the refrigerant gas gradually condenses into a refrigerant liquid, and the external ambient air absorbs heat and becomes hot. The air blown by the condensing fan dissipates heat efficiently.

The evaporator is a device that absorbs heat and vaporizes the refrigerant that has been throttled by the expansion valve to achieve the cooling effect.

Specifically, when the air passes through the evaporator core, heat is taken away by the refrigerant in the core, thereby cooling the air. In order to prevent water droplets from condensing on the evaporator core and being carried into the cabin by the air flow, the outer surface of the evaporator core is coated with a hydrophilic film.

If you need to buy in bulk, please contact us.

The work of the bus air conditioning unit is divided into four processes.

A. Compression process: It absorbs heat in the evaporator and turns it into a low-temperature and low-pressure gaseous refrigerant. After being sucked and compressed by the compressor, it turns into a high-temperature and high-pressure gaseous refrigerant and is discharged into the condenser.

B. Condensation process: After the high-temperature and high-pressure gaseous refrigerant enters the condenser, it dissipates heat to the surrounding ambient air through the condenser radiator under the action of the condenser fan, and at the same time condenses into high-temperature and high-pressure liquid refrigerant.

C. Throttling process: After the high-temperature and high-pressure liquid refrigerant passes through the liquid receiver and filter dryer, it is throttled to cool down and depressurize through the expansion valve, and becomes a mixture of low-temperature and low-pressure liquid and gaseous refrigerant and enters the evaporator.

D. Evaporation process: The refrigerant is throttled by the expansion valve and becomes a mixture of low-temperature and low-pressure liquid and gaseous state. It vaporizes in the evaporator. Under the action of the evaporator fan, it absorbs the heat of the air in the cabin to cool the air in the cabin, and at the same time precipitates condensation. water. After absorbing heat, the refrigerant evaporates into low-temperature and low-pressure gaseous refrigerant, which is sucked into the compressor and then compressed to complete a refrigeration cycle.

The compressor keeps running, the above-mentioned refrigeration process circulates continuously, and the heat in the bus is continuously taken away by the refrigerant in the evaporator, thereby completing the cooling of the bus.

Mainly reflected in the following aspects:

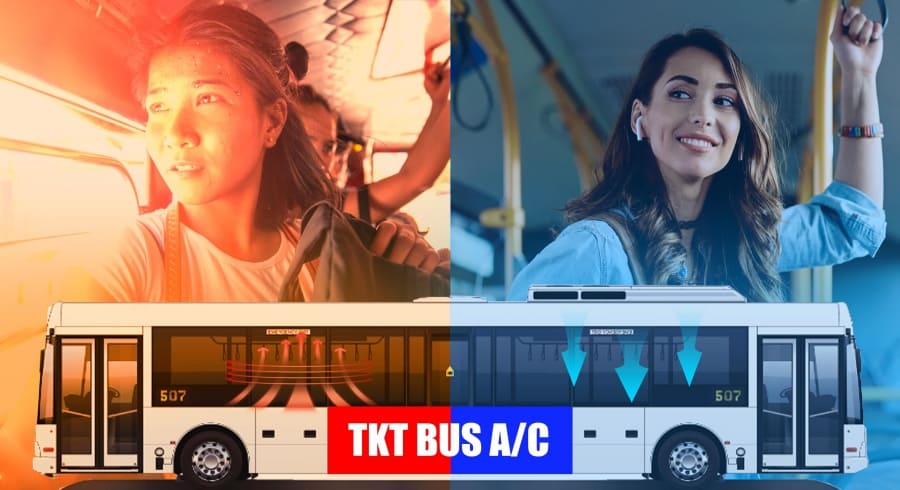

1. Improve the air quality in the bus: The air conditioner can circulate fresh air, discharge the dirty air in the bus, reduce dust, carbon dioxide, bacteria and other harmful substances, and provide passengers with a fresh environment.

2. Improve passenger comfort: In hot summer, air conditioning can control the temperature inside the bus at a temperature that is comfortable for the human body, thereby improving the passenger riding experience.

3. Energy saving and environmental protection: With the development of new energy buses, the design of air conditioning systems is more energy-saving and environmentally friendly, which can effectively reduce energy consumption and reduce the impact on the environment.

CEO Andy founded TKT in Henan, China in 1998. We has advanced cooling technology and manufacturing processes to further improve refrigeration and heat transfer efficiency. If you care about energy saving and environmental protection, we are your best choice.

Email: md@tkt-hvac.com

WhatsApp: +86 13015505615

Facebook: https://www.facebook.com/TKTHVAC/

linkedin: https://www.linkedin.com/company/tkt-hvac

YouTube: https://www.youtube.com/@TKTHVAC