TKT is a leading China EV charger manufacturer. We mainly do export business. Outside TKT's factory, there is an endless stream of transport vehicles from Qingdao, Shanghai, and Ningbo ports. Inside the factory, skilled workers are welding, moving, and debugging in an orderly manner. This ensures that we (TKT company) can complete customers' orders on time and with quality.

"Orders are hot! Production has been scheduled for half a year!" Mr. Qi, the person in charge of the project, said cheerfully. One by one, the new electric vehicle chargers have passed the final inspection and are ready for overseas shipment. The destination of this batch of orders is the leading car companies in Germany, the United Kingdom, India, and other countries.

"Take the Southeast Asian market for example. The local climate is hot and humid, and the roads are dusty. How to increase the service life of China EV chargers? We must continuously optimize and upgrade in combination with the environment of different regions." The person in charge said.

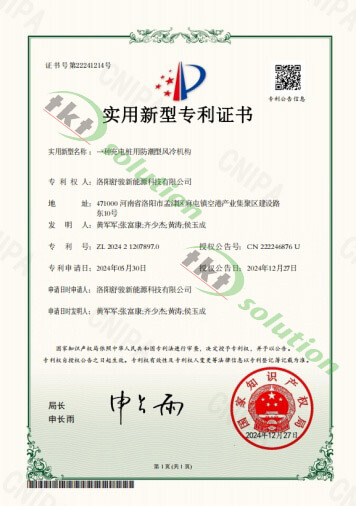

For example, the innovative moisture-proof air cooling structure. This is a patented technology for dehumidifying and cooling the high-temperature and high-humidity gas entering the charger. This patent improves the safety and life of the charger. TKT conducts in-depth research, and one patent technology after another helps companies solve problems, so as to gain a foothold in overseas markets.

In recent years, the global demand for new energy commercial vehicles has become increasingly hot, and the market penetration rate has continued to rise. TKT has taken advantage of this trend, and its orders for electric vehicle chargers have also increased year by year. "In the Indian market, we are a core parts supplier for leading new energy commercial vehicle companies such as TATA and BYD." The person in charge said. As the overseas market gradually opens up, the output value of the project is expected to increase further this year.

Click on the image to enlarge

TKT Group is a technology-based enterprise engaged in the research and development and production of new energy vehicle parts. It has factories in China and India, and the Chinese factory covers an area of 20 acres. It develops and produces electric bus air conditioners, battery thermal management systems, electric vehicle chargers and other products. We take innovative technology as our core competitiveness and layout markets in Europe, Southeast Asia and other regions.

TKT EV Chargers: https://www.busthermo.com/pro_cat/commercial-ev-charger/scenario-based-solutions/

Facebook: https://www.facebook.com/TKTHVAC/

Linkedin: https://www.linkedin.com/company/tkt-hvac

Youtube: https://www.youtube.com/@TKTHVAC

The scale of China EV charging stations is huge and may change at any time. I can only give an approximate value. By the end of January 2025, the cumulative number of EV chargers in China will reach 13.213 million units. Among them, there are 3.76 million public EV chargers and 9.453 million private EV chargers.

The China EV charger market is in a stage of rapid growth. The goal is to build a high-quality charging network with wide coverage by 2030. In the global market, Chinese companies dominate the global charging equipment manufacturing.

The new generation of chargers generally incorporates Internet of Things technology. This enables EV chargers to support remote monitoring, fault diagnosis, dynamic power allocation, etc. On the other hand, the compatibility of Chinese standards with global standards has been improved, reducing compatibility issues.

China is systematically solving the problem of electric vehicle charging through multi-dimensional measures. I will give two of the most easily understood product-related issues.

High-power fast charging technology: Support 900kw high-power charging, achieving "10 minutes to recharge 400 km".

Automation: Apply automatic charging robots, wireless charging and other technologies to further improve charging efficiency.