Es wird auch als Batterie-Wärmemanagementsystem bezeichnet (BTMS), oder Batteriekühlsystem (BCS), oder elektrisches Batterie-Wärmemanagement (eBTM), oder Batteriekühlung, oder Akku-Kühlsystem. Der Hauptzweck besteht darin, sicherzustellen, dass der Akku im optimalen Temperaturbereich Strom entladen kann. Dies sorgt für maximale Stabilität und effiziente Kraftfreisetzung. Derzeit, Die Technik in diesem Bereich der Kleinwagen ist relativ einfach. Bei größeren Fahrzeugen wie Elektrobussen und Elektro-Lkw ist das jedoch selten. Dies liegt daran, dass der Akku eines größeren Fahrzeugs im Betrieb mehr Spannung und Strom erzeugt. Dies erfordert mehr Fachwissen.

Das globale Klima heizt sich weiter auf, und die zunehmende Schwere von Klimakatastrophen in den letzten Jahren verdeutlicht den Ernst der Sache. Der Schutz der Umwelt wird weltweit zu einem wachsenden Anliegen. Länder neigen dazu, mit der Einführung von Elektrobussen und Elektro-Lkw zu beginnen.

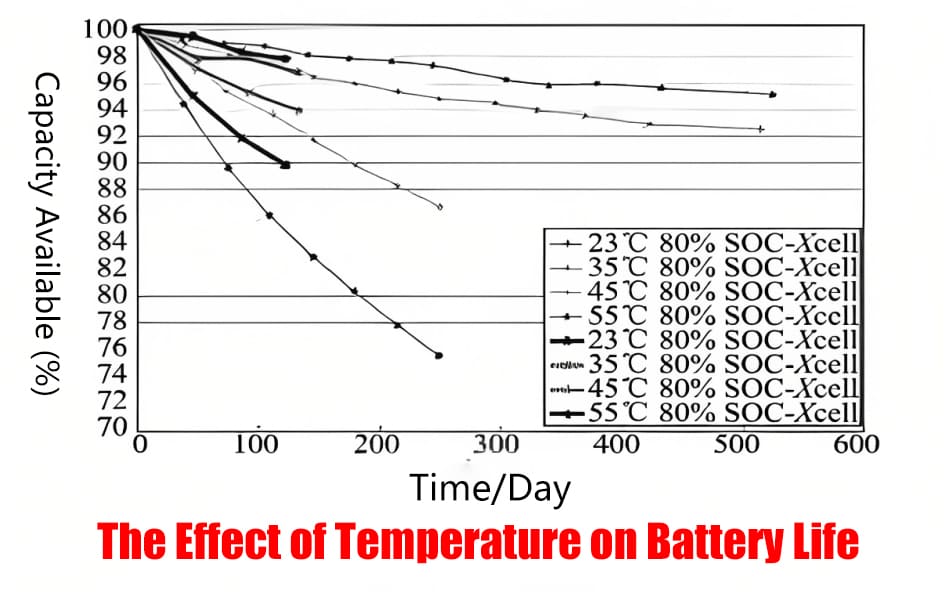

Der Prozess der Energieabgabe aus einer Batterie geht zwangsläufig mit der Freisetzung von Wärme einher. Die optimale Betriebstemperatur für Batterien liegt bei 20° bis 40°, Und wenn diese Temperatur überschritten wird, Dadurch wird nicht nur die Leistung des Akkus verringert, Allerdings verringern sich die Reichweite und die Lebensdauer der Batterie drastisch. Ernsthafter, es kann sich auch auf die umliegenden Geräte auswirken, was zu Verbrennungen und Explosionen führen kann. Hier kommt die Batteriekühlungstechnologie ins Spiel.

| 80% Verbleibende Kapazität - Zeitbeziehung | |

| Temperatur (°C) | Lebensdauer (Tage) |

| 23 | 6238 |

| 35 | 1790 |

| 45 | 670 |

| 55 | 272 |

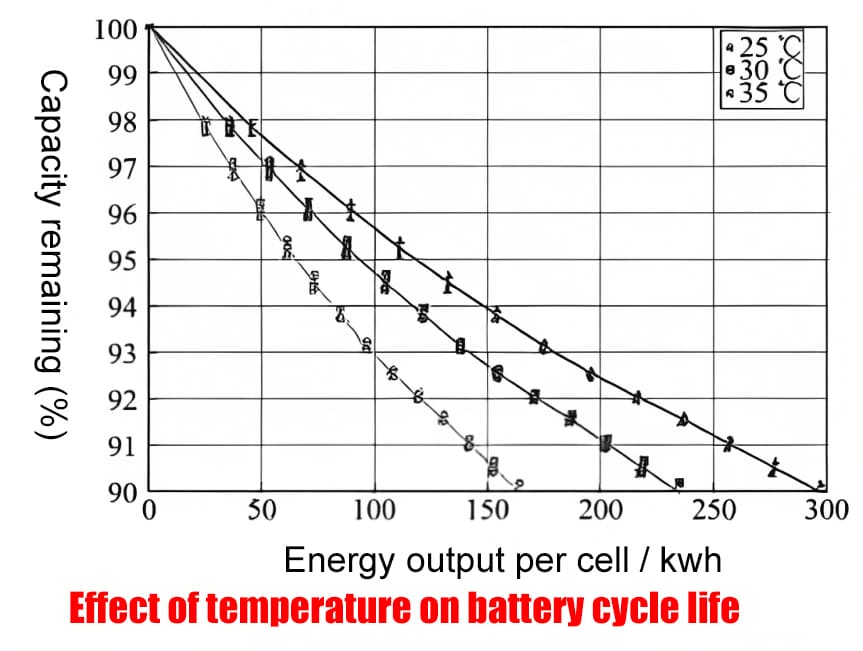

| 90% Verbleibende Kapazität - Energieabgabe | |

| Temperatur (°C) | Kapazitätsausgang (kWh) |

| 25 | 300 |

| 30 | 235 |

| 35 | 163 |

Traditionell, Zur Abfuhr der Wärme wurde Luft verwendet. Die Hitze ist tatsächlich weggeblasen. Ein Luftkühlsystem erfordert ein Luftzirkulationssystem mit Kanälen und Lüftungsöffnungen, eine Ventilatoreinheit, um die Luft zu bewegen, und eine Kühleinheit zum Kühlen der erwärmten Luft, bevor sie in den Kreislauf zurückgeführt wird.

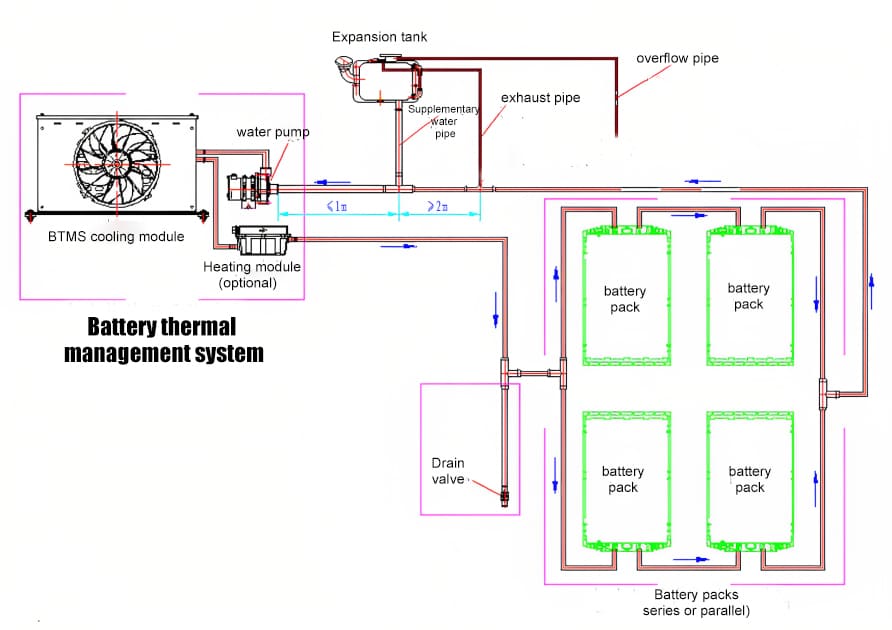

Ein anderer, Eine bessere Möglichkeit, Wärme abzuleiten, ist die Verwendung einer Kühlmittelkühlung. Auch hier ist der Vorgang einfach. Die Wärmequelle weist einen Kühler oder ein mit Flüssigkeit kühlbares Bauteil auf. Kalte Flüssigkeit wird zur Wärmequelle zirkuliert und die erhitzte Flüssigkeit wird abgepumpt und mit einem Wasser-Wasser-Wärmetauscher oder einem Wasser-Luft-Kühler gekühlt. Ein Flüssigkeitskühlsystem erfordert ein Rohrleitungssystem, Pumpstation und einem Wasser-Wasser-Wärmetauscher oder einer Wasser-Luft-Kühleinheit.

Schematische Darstellung von BTMS

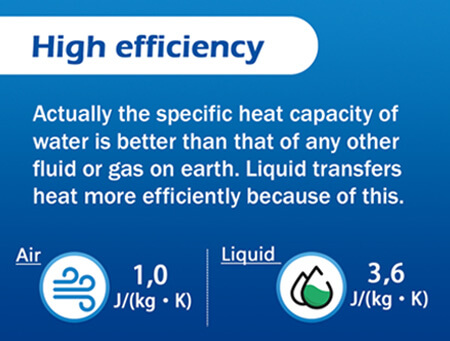

Hohe Effizienz - Tatsächlich ist die spezifische Wärmekapazität von Wasser besser als die jeder anderen Flüssigkeit oder jedes anderen Gases auf der Erde. Dadurch überträgt die Flüssigkeit die Wärme effizienter.

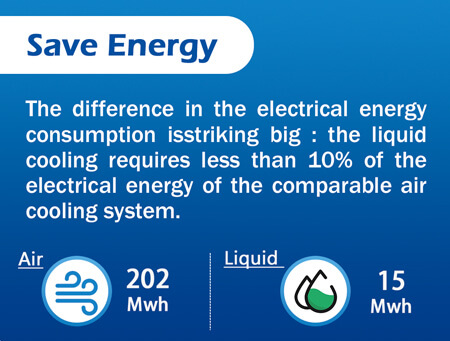

Sparen Sie Energie - Der Unterschied im elektrischen Energieverbrauch ist auffallend groß: Die Flüssigkeitskühlung benötigt weniger als 10% der elektrischen Energie des vergleichbaren Luftkühlsystems!

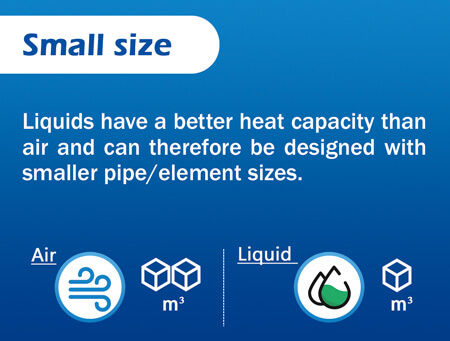

Kleine Größe- Flüssigkeiten haben eine bessere Wärmekapazität als Luft und können daher mit kleineren Rohr-/Elementgrößen ausgelegt werden.

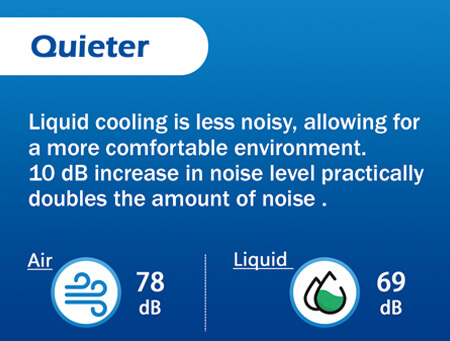

Leiser - Die Flüssigkeitskühlung ist weniger laut, was eine angenehmere Umgebung ermöglicht.

PS. 10 Eine Erhöhung des Geräuschpegels um db führt praktisch zu einer Verdoppelung des Geräuschpegels !

TKT ist auf Batteriekühler für Elektrobusse und Elektro-Lkw spezialisiert. Seitdem erforschen und entwickeln wir Batteriekühltechnologie 2012. Mit 10 Jahre Erfahrung in der Fertigung, Unterstützung von OEM&OEM. Mit dieser Technologie, Elektrobusse und Elektro-Lkw können mit demselben Batteriepaket eine größere Distanz zurücklegen. Der Betrieb der Geräte ist sicherer und stabiler.

In der Vergangenheit 10 Jahre, TKT hat Batteriepack-Kühlsysteme gemäß den Anforderungen verschiedener OEM-Kunden entwickelt und hergestellt. Wie BYD, Yutong und Golden Dragon in China, und TATA Motors in Indien, Daewoo in Korea und anderen Überseemärkten. Die Kühlkapazität und Heizkapazität des Batterie-Wärmemanagementsystems(BTMS) reicht von 3-10KW je nach Kundenwunsch. Wir können die Anforderungen verschiedener Nutzfahrzeuge erfüllen, selbst wenn die Umgebungstemperatur erreicht wird 60 Grad C bzw -20 Grad C. TKT stellt auch auf dem Dach montierte Batteriekühler her, seitlich montiert Batteriekühler und am Fahrgestell montierter Batteriekühler entsprechend den Anforderungen verschiedener Kunden.

Kühlsystem für Akkupack - 3S Klicke, um mehr zu lernen

Kühlsystem für Akkupack- 3R Klicke, um mehr zu lernen

Kühlsystem für Akkupack - 5S Klicke, um mehr zu lernen

Kühlsystem für Akkupack - 5R Klicke, um mehr zu lernen

Kühlsystem für Akkupack - 8S Klicke, um mehr zu lernen

Kühlsystem für Akkupack - 8R Klicke, um mehr zu lernen

Hinterlassen Sie gerne eine NachrichtEmail:md@tkt-hvac.com und lassen Sie sich von unseren Experten kompetent beraten. Wir unterstützen OEM-Anpassungen.