Cargadores de vehículos eléctricos

Sistema de gestión térmica de la batería

Aire acondicionado eléctrico

Aire acondicionado accionado por motor

✲ Personalizado: Dimensión/refrigeración/calefacción, etc..

✲ Top mundial 500 Proveedor BYD/TATA

✲ Más 200,000 unidades en funcionamiento en todo el mundo

✲ 10 Años de experiencia en R&D y Diseño

✲ Certificaciones: YO ASI 9001, IATF 16949, etc..

Solicitud: Sistema de gestión térmica de baterías para autobuses / Camión / Equipo pesado / barco, etc..

La temperatura de funcionamiento óptima de la batería del vehículo eléctrico es de 20° a 45°. Si se excede esta temperatura, La autonomía y la vida útil de la batería disminuirán drásticamente.. Y lo que es más, También puede afectar el equipo circundante y provocar consecuencias de combustión y explosión.. Si la batería está por debajo de esta temperatura, su actividad de reacción electroquímica disminuirá y el rendimiento de la batería se reducirá considerablemente.

El sistema de gestión térmica de baterías es un sistema especialmente diseñado para enfriar baterías eléctricas.. Es un componente indispensable de los vehículos eléctricos comerciales.. El sistema de refrigeración de la batería TKT adopta refrigeración líquida y PTC para calefacción., que puede eliminar constantemente una gran cantidad de calor generado por la batería. Este es el método de enfriamiento de baterías más utilizado para autobuses eléctricos, camiones electricos, equipo pesado electrico, y barcos eléctricos.

Haga clic para obtener más información sobre el principio.

El sistema de gestión térmica de baterías TKT dispone de una amplia gama de soluciones.. La capacidad de refrigeración es de 3 a 10 kW y las posiciones de montaje son de montaje superior y lateral.. También está lo último Sistema integrado BTMS para climatización de autobuses., que es una solución integrada para autobuses eléctricos. TKT también admite el servicio de personalización OEM. podemos resolver 99% de diferentes clientes’ necesidades.

Se ejecuta automáticamente para mantener estable la temperatura de la batería

▲Más de 10 años de prueba de mercado, encima 200,000 unidades en funcionamiento en todo el mundo, con calidad y desempeño ampliamente reconocidos a nivel mundial.

▲ Diseño patentado para lograr una mayor refrigeración/calefacción con menos peso;

▲ Mayor flujo de refrigerante para mantener la temperatura de la batería en la temperatura más corta;

▲ Control CAN para evitar una operación incorrecta que dañe la batería (Se ejecuta automáticamente para mantener estable la temperatura de la batería);

▲ Adopte piezas eléctricas IP67, como compresor eléctrico, bomba de agua, conectores, etc.;

▲OEM rápido/diseño personalizado (1 mes);

▲Control de temperatura preciso (0.5 tu.c);

sobre el pasado 10 años, TKT HVAC se ha desarrollado rápidamente y se ha convertido en el líder 3 fabricantes de sistemas de gestión térmica de baterías en China. Con una rica experiencia OEM, Hemos cooperado con muchos fabricantes de vehículos de fama mundial.. Como BYD, motos tata, Cambiar de movilidad, Daewoo, etc.. Los proyectos cooperativos incluyen una variedad de sistemas de gestión térmica de baterías de autobuses eléctricos., sistema de gestión térmica de batería de camión ligero, sistema de gestión térmica de baterías de camiones pesados, etc..

«Estudio de caso de gestión térmica de baterías de vehículos eléctricos: una historia personalizada para Fortune 500» Haga clic para leer (muy recomendado)

Prueba de vehículo real, operación estable (Haga clic en la imagen para ampliar)

Bienvenido a contactarnos para asesoramiento profesional sobre modelos. Además, TKT proporciona servicios de personalización OEM, y los fabricantes de vehículos pueden consultar.

| Apoyo Personalizado Servicios |

|

|

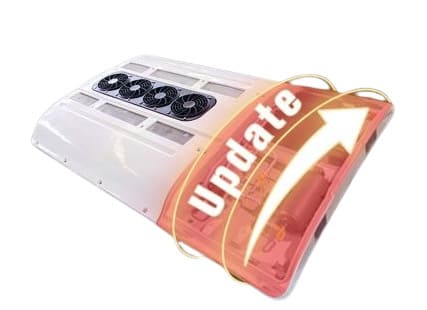

| Capacidad | Enfriamiento: 8-10kilovatios Calefacción: 6-10kilovatios (Opcional) |

Enfriamiento: 5-6kilovatios Calefacción: 3kilovatios (Opcional) |

| Solicitud | 11-12Autobús eléctrico M BTMS (DC240V-DC750V) |

8-10Autobús eléctrico M BTMS (DC240V-DC750V) |

| Producto Modelo |

10R/10CW para EBus Ver página 10R/10CW |

5R/5CW para EBus Ver página 5R/5CW |

| Apoyo Personalizado Servicios |

|

|

| Capacidad | Enfriamiento: 3-4kilovatios Calefacción: 1-2kilovatios (Opcional) |

Enfriamiento: 5-6kilovatios Calefacción: 3kilovatios (Opcional) |

| Solicitud | 6-7Autobús eléctrico M BTMS (DC240V-DC750V) |

Camión eléctrico BTMS (DC240V-DC750V) |

| Producto Modelo |

3R/3CW para EBus Ver página 3R/3CW |

5CW para ETruck Ver página 5CW |

| Apoyo Personalizado Servicios |

|

|

| Capacidad | Enfriamiento: 3-4kilovatios Calefacción: 1-2kilovatios (Opcional) |

Enfriamiento BTMS: 8kilovatios Refrigeración del aire acondicionado del autobús: 143KBTU |

| Solicitud | Equipo pesado electrónico BTMS (DC240V-DC750V) |

Aire acondicionado para autobús eléctrico + BTMS (DC240V-DC750V) |

| Producto Modelo |

3R para EHE Ver página 3R |

Ver página Sistema integrado |

Contáctenos para imágenes de alta resolución

1. Tipo de batería y especificaciones: Los diferentes escenarios de aplicación de la batería tienen diferentes requisitos para el sistema de gestión térmica de la batería.. Por ejemplo, si es una batería de energía y se aplica a un autobús eléctrico, el voltaje de su batería suele estar entre 280v-750v. Cuando un autobús eléctrico está en marcha, la bateria produce mucho calor, que requiere un sistema de refrigeración líquida de batería.

2. Espacio de reserva para vehículos eléctricos: Cuando diferentes fabricantes de vehículos diseñan vehículos nuevos, Se planifica el espacio de diseño de cada parte.. Por ejemplo, porque los camiones eléctricos tienen cajas, Generalmente recomendamos diseñar el sistema de gestión térmica de la batería del camión. (BTMS) en el exterior del camión y adoptando una solución de instalación lateral. La ventaja de esto es que favorece la liberación del rendimiento de disipación de calor y la eficiencia de enfriamiento de la batería es alta.. Por supuesto, También tenemos otras soluciones de enfriamiento de baterías de camiones que pueden resolver 95% de las necesidades de refrigeración de baterías de camiones. Para otro ejemplo, El espacio total de la maquinaria pesada eléctrica es pequeño., Por lo tanto, existen requisitos estrictos sobre el tamaño del sistema de gestión térmica de la batería.. Contamos con soluciones de enfriamiento de batería dividida y también brindamos servicios personalizados., para que podamos resolver perfectamente las necesidades del sistema de gestión térmica de baterías de diferentes tamaños.

3. Calidad y confiabilidad: El sistema de gestión térmica de la batería. (BTMS) Es muy importante para los vehículos eléctricos.. No solo puede garantizar la seguridad del vehículo sino también reducir los costos operativos del vehículo.. Un sistema de refrigeración de alta calidad puede mejorar enormemente la duración de la batería y la autonomía del vehículo, reduciendo así los costos de reemplazo de baterías y los costos de carga de vehículos. Por eso es muy importante elegir un buen sistema de gestión térmica de la batería.. Los productos TKT BTMS han sido suministrados a Fortune 500 compañías, pasó sus estrictas inspecciones, y han estado en funcionamiento real del vehículo durante más de 5 años. Sólo la práctica puede decir si un producto es bueno o no.. Cinco años de funcionamiento estable es la mejor prueba.. TKT tiene una rica experiencia en cooperación con fabricantes de vehículos OEM, como proyecto BYD, Proyecto de motores TATA., Proyecto de movilidad Switch, etc..

Bobina de condensador, abanico condensador, depósito de agua, bomba de agua, intercambiador de calor, compresor electrico, Panel de control, módulo CAN, válvula de expansión, etc..

El sistema de condensador enfría el refrigerante y la bomba de agua hará pasar el refrigerante a través del BTMS y el sistema de estructura de la batería para liberar el calor generado por el paquete de baterías..

El sistema de gestión térmica de la batería se divide principalmente en refrigeración por aire de la batería., refrigeración líquida de la batería, enfriamiento del material por cambio de fase, y refrigeración por inmersión de la batería. Es necesario seleccionar diferentes métodos de enfriamiento según el criterio del escenario.. Para vehículos eléctricos comerciales, porque la capacidad de la batería de los vehículos eléctricos es relativamente grande, todas son baterías de alto voltaje, entonces desprenden mucho calor. Ahora el programa más rentable y estable es la refrigeración líquida de la batería..

La función del sistema de gestión térmica de la batería es ajustar la temperatura de la batería en tiempo real y mantenerla funcionando dentro del rango de temperatura óptimo para garantizar el rendimiento de la batería., vida y seguridad. Principalmente hablando, se divide en las siguientes situaciones.

1. Prevenir el sobrecalentamiento: Cuando la temperatura de la batería es demasiado alta, El rendimiento de la batería se verá afectado e incluso puede funcionar mal.. El sistema de gestión térmica de la batería puede reducir la temperatura de la batería a tiempo mediante la disipación de calor y otros métodos para evitar que la batería se sobrecaliente..

2. Prevenir el sobreenfriamiento: En ambientes de baja temperatura, El rendimiento de la batería también se verá afectado e incluso puede dejar de funcionar correctamente.. El sistema de gestión térmica de la batería puede aumentar rápidamente la temperatura de la batería mediante calentamiento y otros métodos para evitar que la batería se enfríe demasiado..

3. Mantener la estabilidad de la temperatura de la batería: Durante la conducción del vehículo, la temperatura de la batería seguirá cambiando. Si la fluctuación de temperatura es demasiado grande, tendrá un impacto negativo en el rendimiento de la batería. El sistema de gestión térmica de la batería puede mantener estable la temperatura de la batería controlando el flujo de refrigerante y otros métodos..

4. Mejorar la duración de la batería: Controlando la temperatura de la batería dentro del rango óptimo, la duración de la batería se puede extender. Reducir el número de reemplazos y reducir los costos de mantenimiento..

La tecnología de refrigeración de baterías es más exigente para el diseño de autobuses y camiones eléctricos, en el que TKT ha estado trabajando desde 2012.

La solución más eficaz para mejorar la autonomía sin aumentar el número de baterías es un sistema de gestión térmica de baterías personalizado..

Caso de gestión térmica de batería EV – Personalizado para la fortuna 500. El BTMS de TKT tiene 10 años de experiencia en diseño.