The main function of the electric bus air conditioner system is to maintain the temperature, kelembaban, Kebersihan udara dan aliran udara di kabin dalam keadaan yang nyaman. Sistem pendingin udara adalah komponen yang paling memakan energi kedua dari bus listrik. Pembukaan sistem pendingin udara umumnya mengurangi rentang mengemudi dengan 25% ke 30%. Karena itu, Saat Mengembangkan Bus Listrik, perlu untuk fokus mengoptimalkan desain sistem pendingin udara pendukung. Ini dapat mengurangi konsumsi pendingin udara dan meningkatkan tujuan perjalanan bus.

AC bus listrik TKT

Pendingin udara listrik pada bus listrik memiliki karakteristik utama berikut dibandingkan dengan sistem pendingin udara biasa.

1, Sistem pendingin udara listrik dipasang pada kendaraan yang bergerak, untuk menahan getaran dan getaran kekerasan dan sering, membutuhkan bahwa setiap bagian dari struktur perangkat pendingin udara listrik harus memiliki kekuatan yang cukup untuk menahan getaran dan guncangan dan kinerja sistem kedap udara yang baik.

2, Sebagian besar bus listrik adalah penumpang jarak pendek, Waktu perjalanan singkat, ditambah dengan jumlah orang yang mengendarai kendaraan, Produk yang relatif lebih panas, beban panas relatif, Membutuhkan AC dengan pendinginan cepat, fungsi pendinginan.

3, Pendingin udara listrik menggunakan daya DC yang disediakan oleh baterai daya, Kompresor listrik dengan efisiensi tinggi, keandalan kontrol yang tinggi dan pemeliharaan yang mudah.

4, Efek isolasi tubuh bus buruk, dan area kaca besar, Radiasi panas yang memperburuk, Sementara ada dua penumpang di depan dan di belakang bus, membuka frekuensi tinggi, menghasilkan konveksi yang serius di dalam dan di luar kendaraan.

5, fasilitas bus di dalam ketinggian dan kursi yang tidak rata, Kesulitan organisasi distribusi aliran udara, sulit untuk mencapai distribusi aliran udara yang seragam.

Kasus OEM untuk keberuntungan TKT 500

Pada prinsipnya, Sistem ini tidak berbeda dengan AC biasa. Namun, untuk digunakan di bus listrik, Kompresor baling -baling geser ruang kerja ganda, Motor DC Brushless, dan sistem kontrol inverter telah dikembangkan secara khusus.

AC listrik untuk bus listrik memiliki kompresor, alat penguap, Kondensor dan komponen lainnya semuanya terintegrasi dalam satu. Dan juga tidak ada pipa bertekanan tinggi dan rendah di antara itu dan kompartemen mesin, Jadi lebih mudah diatur dibandingkan dengan sistem pendingin udara di bus bahan bakar konvensional, yang juga biasanya mengadopsi pengaturan overhead.

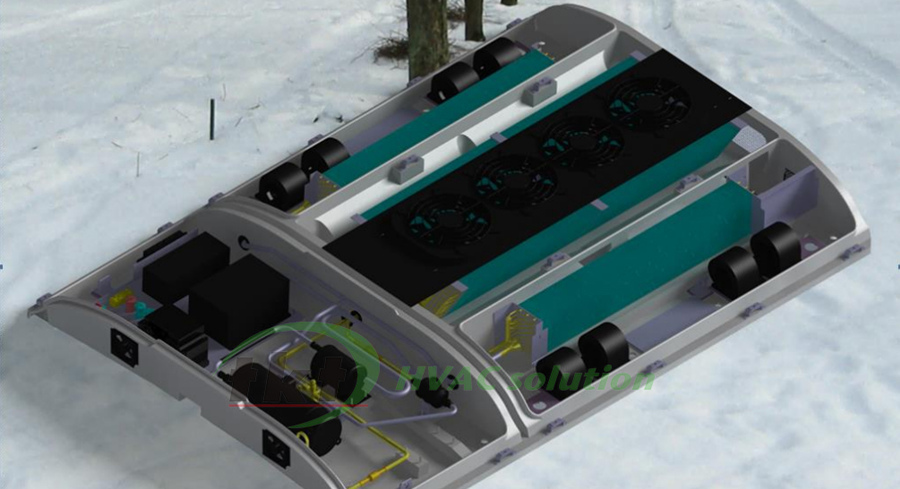

TKT Bus AC 3D Design Drawing

Pendingin udara listrik bus listrik mengintegrasikan komponen seperti kompresor, alat penguap, dan kondensor. Lebih mudah diatur daripada sistem pendingin udara di bus bahan bakar tradisional. Menurut distribusi beban di roda depan dan belakang, Panjang pipa bertekanan tinggi dan rendah, Susunan sirkuit kontrol dan lokasi outlet udara dan outlet udara kembali, dan mempertimbangkan posisi relatif peralatan lain di atap. Tipe yang dipasang di atas dapat dibagi menjadi terpasang di depan, terpasang di tengah dan dipasang di belakang.

Pembangun tubuh bus koperasi

TKT telah sepenuhnya mengembangkan peralatan pendingin udara dengan teknologi penggerak listrik murni sejak itu 2012, berbicara pada gilirannya:

1, Getaran dan ketahanan guncangan dari masing -masing komponen dalam sistem listrik murni.

Fungsi pendinginan dan pendinginan yang lebih cepat.

2, Kemampuan kontrol keselamatan untuk kompresor listrik.

3, Distribusi aliran udara yang seragam dan masuk akal.

4, Menyediakan layanan OEM, Untuk berbagai jenis bus, Kami menyediakan layanan khusus.

5, Dengan pengalaman OEM yang kaya. Kami memiliki layanan OEM dengan Tata, Top dunia 500 perusahaan, untuk ratusan bus.

TKT HVAC - Atas 1 Produsen A/C Bus di China

Untuk mempelajari lebih lanjut tentang AC bus TKT, silakan klik Di Sini.

Untuk membeli produk atau untuk kerja sama lainnya, Hubungi kami, klik Di Sini.

Facebook: https://www.facebook.com/TKTHVAC/

Linkedin: https://www.linkedin.com/company/tkt-hvac

Youtube: https://www.youtube.com/@TKTHVAC