produk

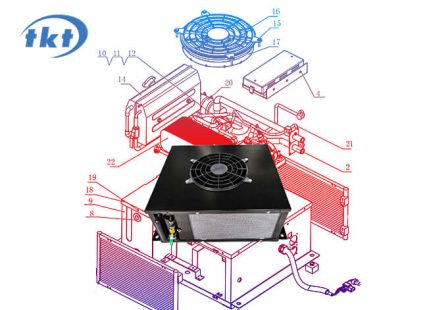

Battery Chillers is to reduce the temperature of the battery in the operation. A running battery, if kept within a reasonable temperature range, will result in more power and driven distance for electric equipment and longer battery life. We also call it battery thermal management system or BCS, BTMS.

TKT started designing and manufacturing Battery Chillers in 2012 for various electric equipment. TKT has developed a series of products to solve the problem of battery temperature. These products offer a variety of outstanding advantages, such as achieving precise temperature control (0.5°C), product lightweighting studies, and products that have passed 10 pengujian pasar selama bertahun-tahun, among other reasons.

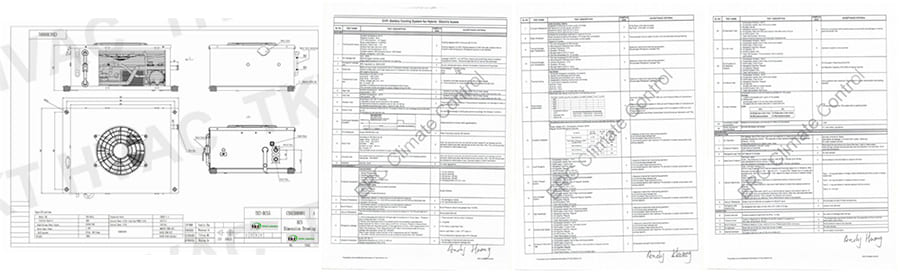

Catatan: This is a highly customizable part and we can manufacture it exactly to the customer’s specifications. Pendinginan, pemanas, ukuran, dll.. can all be customized.

Produk TKT ada banyak jenisnya. Selamat Datang di Hubungi kami untuk saran ahli atau Surel:md@tkt-hvac.com.

Disesuaikan: Dimensi/ pendinginan/ pemanas

OEM cepat/desain yang disesuaikan (1 bulan)

Kontrol suhu yang tepat (0.5 Anda.C)

Dapat mengontrol untuk menghindari operasi yang salah untuk merusak baterai

Disesuaikan: Dimensi / pendinginan / pemanas

Fast OEM / Customized Design (1 bulan)

Teknologi Inovatif: Kami menggabungkan A/C bus listrik dan sistem pendingin baterai untuk membentuk sistem manajemen termal EV yang lebih komprehensif.

✲ Kapasitas pendinginan A/C E-bus: 42KW / 143K BTU

✲ kapasitas pendinginan BCS: 8KW (Pemanasan opsional)

✲ Aplikasi: Bus Listrik Murni

✲ Keuntungan: Meningkatkan Efisiensi, Menghemat Ruang, Perbaikan Lebih Sedikit, Menghemat Biaya

✲ Disesuaikan: Dimensi/ pendinginan/ pemanas dll.

✲ Puncak Dunia 500 Pemasok BYD/ TATA

✲ lebih 200,000 unit yang beroperasi di seluruh dunia

✲ 10 Pengalaman tahun di R&D dan desain

✲ Sertifikasi: ISO 9001, IATF 16949, dll..

Aplikasi: Sistem manajemen termal baterai untuk bus / Truk / Alat berat / perahu dll.

Di masa lalu 10 bertahun-tahun, TKT telah merancang dan memproduksi Sistem Pendingin Paket Baterai sesuai dengan kebutuhan pelanggan OEM yang berbeda, seperti BYD, Yutong dan Naga Emas di Tiongkok, dan TATA Motors di India, Daewoo di Korea dan pasar luar negeri lainnya. Kapasitas pendinginan dan kapasitas pemanasan Sistem Manajemen Termal Baterai(BTMS) berkisar dari 3-10KW sesuai dengan kebutuhan pelanggan, yang dapat memenuhi persyaratan kendaraan komersial yang berbeda meskipun suhu lingkungan mencapai 60 derajat C atau -20 derajat C. TKT juga membuat Battery Chiller yang dipasang di atap, Battery Chiller yang dipasang di samping dan Battery Chiller yang dipasang di sasis sesuai dengan kebutuhan pelanggan yang berbeda.

“EV Studi Kasus Manajemen Termal Baterai - Kisah Kustom untuk Keberuntungan 500” Klik untuk membaca (sangat disarankan)

Hubungi kami untuk gambar resolusi tinggi

“Harta benda 500 Proyek Sistem Manajemen Termal Baterai Truk Tata” Klik untuk membaca

“Battery Chiller Focus On Truck & Bus dll. - Solusi Tingkat Lanjut Dewasa” Klik untuk membaca (sangat disarankan)

“Battery Chiller customization solutions and common customization directions” Klik untuk membaca

Professional manufacturer & supplier of vehicle air conditioning system and battery thermal management system. Both technical strength and output are in a leading position. TKT punya 25 insinyur dengan gelar master dan doktor, 480 pekerja dengan 4-8 pengalaman perakitan selama bertahun-tahun, Dan 85 negara untuk memberi Anda layanan purna jual yang sempurna. Produk utama memiliki CE, EMI/EMC certification.