Disesuaikan: Dimensi/ pendinginan/ pemanas

OEM cepat/desain yang disesuaikan (1 bulan)

Kontrol suhu yang tepat (0.5 Anda.C)

Dapat mengontrol untuk menghindari operasi yang salah untuk merusak baterai

The operation of the battery is accompanied by the process of charging and discharging, which will generate a lot of heat. Especially during fast charging and high power discharging. A large amount of heat, if not cooled down, will render electrically powered equipment unable to function properly. Therefore a device is needed to reduce the temperature of the battery during operation. Such equipment is generally called battery cooling system, also referred to as BCS or BTMS.

Berjalan secara otomatis untuk menjaga suhu baterai tetap stabil

Seperti yang kita semua tahu, oil is a non-renewable resource, it will become less and less in the future. Pada saat yang sama, the earth’s environment is getting worse and worse, and the greenhouse effect is becoming more and more obvious. Karena itu, the development of pure electric vehicles, pure electric aircraft, pure electric ships and other pure electric drive equipment is the only way for future development.

Compared with the various equipment driven by the engine, the equipment driven by pure electricity will have stricter temperature requirements. This is because the optimal temperature of the battery is between 20-45 derajat. If the battery temperature exceeds this range, it will accelerate the life of the battery and equipment, accelerate corrosion damage, dll., and even cause the equipment to burn. If the battery falls below this temperature, it will result in reduced battery performance, which will eventually result in underpowered devices or reduced mileage. The development of pure electric drive equipment must solve this problem.

TKT punya 10 years of experience in R&D and design of BTMS, and more than 200,000 devices are in operation around the world. They are certified for real results. We provide professional customization services and can do custom development for other types of equipment. Including size, kapasitas pendinginan, voltage and current, fan direction, dll., welcome to leave a message for detailed communication.

▲ lebih dari 10 tahun bukti pasar, lebih 200,000 unit yang beroperasi di seluruh dunia, dengan kualitas dan kinerja yang diakui secara luas di seluruh dunia.

▲ Desain paten untuk membuat pendinginan/pemanasan yang lebih tinggi dengan lebih sedikit;

▲ Aliran pendingin yang lebih besar untuk menjaga suhu baterai dalam suhu terpendek;

▲ DAPAT Mengontrol untuk menghindari pengoperasian yang salah yang dapat merusak baterai;

▲ Mengadopsi komponen listrik IP67, seperti kompresor listrik, pompa air, konektor dll;

▲ OEM cepat/desain yang disesuaikan (1 bulan);

▲ Kontrol Suhu Yang Tepat (0.5 Anda.C);

360-gelar surround stereo menembak 10kW baterai manajemen termal (Klik untuk bermain)

Di masa lalu 10 bertahun-tahun, TKT telah merancang dan memproduksi Sistem Pendingin Paket Baterai sesuai dengan kebutuhan pelanggan OEM yang berbeda, seperti BYD, Yutong dan Naga Emas di Tiongkok, dan TATA Motors di India, Daewoo di Korea dan pasar luar negeri lainnya. Kapasitas pendinginan dan kapasitas pemanasan Sistem Manajemen Termal Baterai(BTMS) berkisar dari 3-10KW sesuai dengan kebutuhan pelanggan, yang dapat memenuhi persyaratan kendaraan komersial yang berbeda meskipun suhu lingkungan mencapai 60 derajat C atau -20 derajat C. TKT juga membuat Battery Chiller yang dipasang di atap, Battery Chiller yang dipasang di samping dan Battery Chiller yang dipasang di sasis sesuai dengan kebutuhan pelanggan yang berbeda.

“EV Studi Kasus Manajemen Termal Baterai - Kisah Kustom untuk Fortune 500” Klik untuk membaca (sangat disarankan)

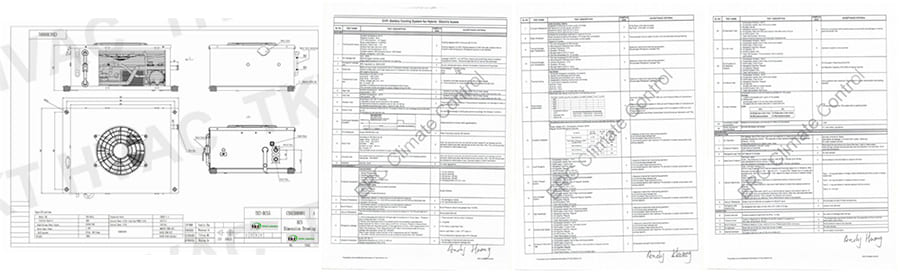

Hubungi kami untuk gambar resolusi tinggi

TKT HVAC didirikan pada 1998, dengan 25 Insinyur dengan gelar master dan PhD, 480 pekerja dengan 4-8 pengalaman perakitan selama bertahun-tahun, Dan 85 negara untuk memberi Anda layanan purna jual yang sempurna. lebih dari 210 paten dan CE, Sertifikasi EMI/EMC untuk produk utama.

Pelajari lebih lanjut tentang TKT

Kumparan kondensor, kipas kondensor, tangki air, pompa air, penukar panas, kompresor listrik, panel kontrol, modul BISA, katup ekspansi, dll..

Sistem kondensor mendinginkan pendingin dan pompa air akan menjalankan pendingin melalui BCS dan sistem struktur baterai untuk melepaskan panas yang dihasilkan oleh paket baterai.

Ketentuan Pembayaran

Untuk pesanan kecil:

1)100% T/t di muka dapat diterima

2)menerima pembayaran dari sistem jaminan perdagangan Alibaba

Untuk pesanan bernilai besar:

50% Setoran t/t, 50% saldo sebelum pengiriman

Kebijakan Garansi

1) 18 Waktu garansi gratis bulan;

2) Suku cadang gratis yang dikirimkan sebelumnya;

3) Layanan gratis lokal selama periode garansi;

Produk dan aksesori tertentu mungkin lebih lama, Silakan tinggalkan pesan untuk konsultasi terperinci.

Solusi paling efektif untuk meningkatkan jangkauan berkendara tanpa menambah jumlah baterai adalah sistem manajemen termal baterai khusus.

Kasus Manajemen Termal Baterai EV – Disesuaikan untuk Keberuntungan 500. BTMS TKT memiliki 10 pengalaman desain selama bertahun-tahun.

Teknologi pendingin baterai lebih menuntut untuk desain bus listrik dan truk listrik, yang telah dikerjakan TKT sejak itu 2012.