Panoramica della gestione termica della batteria

Sistema di gestione termica della batteria Mantenere le temperature del pacco della batteria del veicolo elettrico all'interno della giusta gamma per mantenere la gamma di guida più lunga e prolungare la durata della batteria. Lo chiamiamo anche batteria BTMS o refrigeratore della batteria o sistema di raffreddamento al pacco batteria.

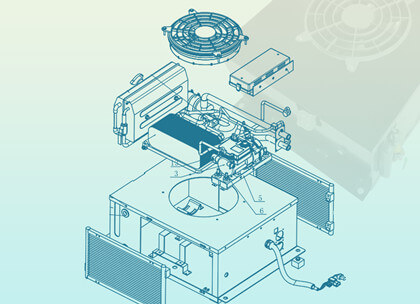

TKT Busthermo è specializzato nello sviluppo di sistemi di gestione termica per batterie per autobus elettrici, batterie per camion elettriche, Batterie per barche elettriche e batterie per attrezzature pesanti elettriche. Con una capacità di raffreddamento/riscaldamento di 3KW-10KW, Mantengono la temperatura del pacco batteria di alimentazione nell'intervallo ottimale mediante raffreddamento del refrigerante e riscaldamento PTC. Ciò consente ai veicoli elettrici di ottenere una durata più lunga e una durata.

Vantaggi di gestione termica della batteria TKT

Ora sempre più al top del mondo 500 I produttori di veicoli scelgono il sistema BTMS TKT, come BYD, Motori Tata, Cambia mobilità, Caterpillar Cat e molti altri. Principalmente grazie a noi:

1. I prodotti BTMS sono di buona qualità e hanno superato il test di mercato per 10 anni.

2. Controllo preciso della temperatura (0.5℃), peso leggero, eccetera..

3. Prezzo giusto e attraente.

4. Inoltre, Questa è una parte altamente personalizzabile e possiamo realizzarla esattamente secondo le specifiche del cliente. Raffreddamento, riscaldamento, dimensioni, e molto altro ancora può essere personalizzato.

Soluzione di gestione termica della batteria

Esistono molti tipi di prodotti TKT. Benvenuto a Contattaci per una consulenza di esperti o E-mail:md@tkt-hvac.com.

Notizie correlate al sistema di raffreddamento del pacco batteria

“Fortuna 500 Progetto del sistema di gestione termica della batteria del camion TATA” Clicca per leggere

“Gestione termica della batteria Focus sul camion & Autobus ecc. – Soluzioni avanzate mature” Clicca per leggere (altamente raccomandato)

“Soluzioni di personalizzazione della gestione termica della batteria e direzioni di personalizzazione comuni” Clicca per leggere

Gestione termica della batteria partner importanti

Conoscenza scientifica della gestione termica della batteria

Cos'è il sistema di gestione termica della batteria?

Sistema di gestione termica della batteria (BTMS) è un sistema di controllo della temperatura chiuso composto da un mezzo di condanna al calore, Unità di misurazione e controllo, e apparecchiatura di controllo della temperatura. Fa funzionare la batteria di alimentazione nell'intervallo di temperatura appropriato per mantenere il miglior stato di utilizzo per garantire le prestazioni e la durata del sistema della batteria.

Una revisione sulla gestione termica della batteria nell'applicazione dei veicoli elettrici (importanza)

La batteria di alimentazione è l'unica fonte di energia per i veicoli elettrici e un indicatore importante che influenza le prestazioni dei veicoli elettrici. Accompagnerà un certo calore durante il processo di ricarica e scarico, che farà aumentare la temperatura, e l'aumento della temperatura influenzerà molti parametri delle caratteristiche di lavoro della batteria, come la resistenza interna, voltaggio, Soc, capacità disponibile, Efficienza di ricarica e scarica, e durata della batteria.

Il problema degli effetti termici della batteria di alimentazione influenzerà le prestazioni e la durata del ciclo del veicolo. Perciò, La gestione termica della batteria è molto importante per le prestazioni e la durata della batteria e il chilometraggio del veicolo.

Quali sono i diversi tipi di sistemi di gestione termica della batteria (BTMS) ?

Attualmente, È principalmente diviso nel raffreddamento dell'aria, raffreddamento liquido, Cambiamento di fase Cambiamento di raffreddamento del materiale e raffreddamento ad immersione. Per il sistema di raffreddamento a batteria EV, Il raffreddamento liquido è la soluzione più comune e stabile.

Raffreddamento liquido a batteria: La batteria scambia la riscaldamento con il refrigerante attraverso la piastra di raffreddamento. Il refrigerante raffreddato o riscaldato viene inviato nello scambiatore di calore da una pompa dell'acqua, e lo scambio di calore e lo shunt vengono eseguiti al suo interno, Così formando un sistema di raffreddamento liquido continuo e stabile per la batteria. Un ciclo virtuoso.

Raffreddamento dell'aria della batteria: Utilizza principalmente il principio di lavoro della convezione dell'aria per far circolare l'aria nel vano batteria. L'aria circolante rimuove il calore dalla batteria, abbassando così la temperatura della batteria. Lo svantaggio è che l'efficienza di raffreddamento è relativamente bassa, soprattutto in ambienti ad alta temperatura.

Materiale di cambio di fase della batteria (PCM) raffreddamento: I materiali PCM sono utilizzati principalmente per trasformarsi tra solido e liquido a temperature ambiente specifiche, realizzando così le funzioni di dissipazione del calore e riscaldamento della batteria. Gli svantaggi sono un'efficienza di raffreddamento relativamente bassa e la necessità di sostituzione regolare dei materiali di cambio di fase.

Raffreddamento a immersione a batteria: Posizionando la batteria direttamente con uno speciale liquido di raffreddamento, Gli effetti di convezione e conduzione del liquido vengono utilizzati per trasferire rapidamente il calore generato dalla batteria al liquido di raffreddamento, ottenendo così l'effetto di raffreddamento della batteria. Gli svantaggi sono requisiti più elevati per il refrigerante e gli alti costi di manutenzione.

Come funziona la gestione termica della batteria?

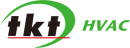

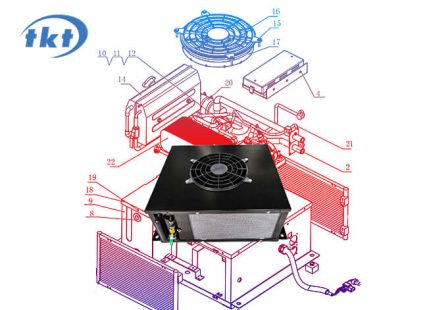

Il sistema di raffreddamento liquido per batteria è costituito da un compressore, condensatore, valvola di espansione, Scambiatore di calore, pompa elettronica dell'acqua, Riscaldatore di liquido PTC, serbatoio di espansione, e controllo elettrico. Quando la batteria deve essere raffreddata per il funzionamento, La batteria scambia la riscaldamento con il refrigerante attraverso la piastra di raffreddamento, e il refrigerante riscaldato viene inviato nello scambiatore di calore dalla pompa elettronica dell'acqua. Il refrigerante viene introdotto in un lato dello scambiatore di calore e il refrigerante viene introdotto nell'altro lato. I due scambiano calore nello scambiatore di calore, in modo che il calore sia portato via dal refrigerante. Il refrigerante freddo scorre fuori dallo scambiatore di calore e poi scorre nella batteria. Il sistema forma un ciclo; Quando la batteria è a bassa temperatura e deve essere riscaldata, Il circuito di refrigerazione è chiuso e il riscaldatore del liquido PTC è acceso. Il refrigerante viene riscaldato e inviato nella batteria, e la batteria viene riscaldata attraverso la piastra di raffreddamento. La gestione termica della batteria controlla la temperatura interna della batteria controllando e spento il circuito di refrigerazione e il riscaldatore del liquido PTC.

Qual è la differenza tra BMS e BTMS?

Semplicemente, BMS è un sistema di gestione della batteria, che include una gamma più ampia. BTMS è il sistema di gestione termica della batteria e fa parte del BMS. Il funzionamento automatizzato di BTMS richiede istruzioni da BMS. Può essere inteso come la relazione tra il cervello e gli arti.

Altre espressioni di uso comune

Batteria raffreddata ad acqua, pacco batteria raffreddato liquido, Gestione termica delle batterie, Sistema di raffreddamento per il pacco batteria, Unità di raffreddamento a batteria, Sistema di gestione termica della batteria BTMS, sistema di raffreddamento a batteria al litio, Batteria per ioni di litio raffreddamento, Gestione termica batteria a ioni di litio, Sistema di gestione della temperatura della batteria, raffreddamento a batteria al litio, Sistema di gestione termica della batteria per veicoli elettrici, Gestione termica della batteria, Sistema di raffreddamento a batteria nel veicolo elettrico, Sistemi di raffreddamento della batteria EV, Sistema di gestione termica della batteria del veicolo, Sistema di raffreddamento della batteria del veicolo elettrico, Sistema di raffreddamento della batteria del veicolo elettrico, Sistema di raffreddamento a batteria ad alta tensione, Termomane di batterie, EV Sistema di gestione termica della batteria, Gestione termica del pacco batteria, Batteria di raffreddamento liquido.