China electric bus charger manufacturer. Provides customized solutions for electric bus charging.

✲ One Hour Charge: E-Bus Adds About 240-480km

✲ High Charging Power: 120kW to 240kW

✲ Robust and Reliable: CE, ARAI and other certificates

✲ Intelligent Management System: Convenient for operation management

✲ High Compatibility: CCS2, チャデモ, GBTと

TKT electric bus charging stations have been developed, designed, and manufactured since 2014. We have extensive OEM experience. Our smart, fast charging systems are designed to meet the needs of public transport fleets, including providing OEM customization. 現在, we are working with some of the world’s top 500 customers such as BYD and TATA motors.

Electric buses, as a mode of public transportation, are usually required to operate around the clock. High passenger capacity, frequent starting and stopping, and energy consumption of auxiliary equipment such as air conditioners result in much higher power consumption than ordinary electric vehicles. したがって, they are usually equipped with a larger battery capacity, which reduces the number of recharging times. They are also usually equipped with faster charging speeds to ensure continuous operation.

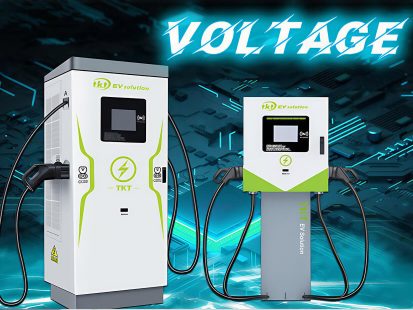

For all these reasons, we have designed this electric bus charging solution: 120~240kW. It has two charging ports and can charge two electric buses at the same time, which can increase the utilization rate. 第二に, it has a very fast charging speed, which can significantly reduce the charging dwell time of electric buses.

120-240 KW DC高速充電ステーション (Click for details)

Electric buses generally consume between 56 そして 60 あたりの電力量kWh 100 kilometers. If a 120kW charger is used to charge an electric bus, theoretically, 120 kWh of electricity can be charged per hour. The range of the electric bus is then approximately 240 kilometers. It should be noted that the actual charging efficiency and range may be affected by a number of factors, such as the efficiency of the charger, ambient temperature, vehicle load, 等. The above calculations are for reference only.

If a 120kw electric bus charging station charges two electric buses at the same time, the charging power of each vehicle will become 60kw.

1.1 Advanced power semiconductor materials: TKT chargers use advanced power semiconductor materials such as silicon carbide (SiC) to improve conversion efficiency and reduce energy loss.

1.2 モジュラー設計: 30kW/40kW high power charging module is adopted as the base. The modular design allows the charger to flexibly expand the charging power according to your needs.

2.1 Multi-standard interface design: support CCS2, GBT, and other charging interfaces, compatible with BYD, 裕通, TATA motors and other brands of buses.

2.2 Automatic recognition of protocol adaptation: Built-in multiple communication protocol stacks automatically recognize the charging protocols of connected electric bus charging. This improves compatibility with a wide range of electric buses and ensures a safe and fast-charging experience.

2.3 More flexible than pantograph charger: not picking the model of electric buses, it is more flexible to be used as and when it comes.

3.1 Multiple protection mechanisms, including overload protection, 短絡保護, 漏れ防止, over-temperature protection, 等, ensure the safe operation of the equipment in various working conditions.

3.2 High-quality components: selected components of famous international brands to ensure product stability and durability.

3.3 Failure self-diagnostic function: real-time monitoring of the state of the equipment, automatic detection and recording of fault information, to facilitate maintenance personnel to quickly locate the problem.

4.1 Human-computer interaction interface: Equipped with high-definition touch screen, supporting multi-language switching, intuitive operation, and improving user experience.

4.2 Cloud platform management: Provide a cloud-based management platform, support remote monitoring, data analysis, 障害診断, and other functions to improve operational efficiency.

TKT には、ハードウェアおよびソフトウェア システムのオンライン サポートを提供する専用のサービス チームがあります。. 何か問題が起きても慌てる必要はありません.

オリジナルの電気自動車充電器メーカーとして, TKT は適切なメンテナンスとトラブルシューティングに関するトレーニングも提供します. This will help extend the life of the electric bus charging station.

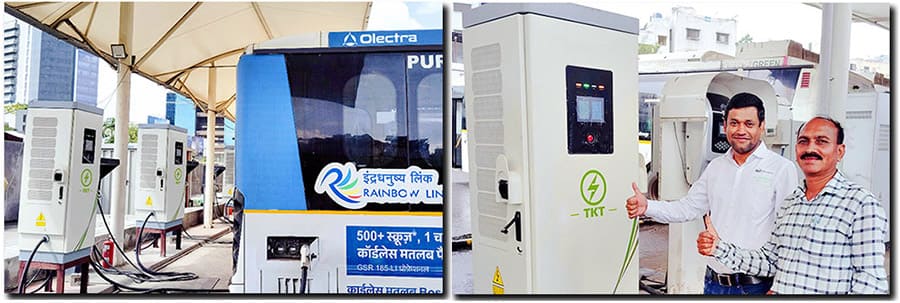

このプロジェクトはBYD-Olectraとのパートナーシップです。, インドの大手電気バスメーカー. 電気自動車の急速充電器の数は、最初のバッチですでに数百を超えています.

主任電気技師として, 氏. ディネシュ氏は充電インフラの構築と保守を主導した. 彼は言いました, “Your electric vehicle chargers played a key role in our project. It has greatly increased the frequency of bus trips.”

一般的に 2 年. 特別なご要望がある場合は、カスタマーサービスまでご連絡ください。. リードタイムは 30-45 営業日, 数量と生産スケジュールによって異なります.

電気バスのバッテリー容量は大きいです, so they need a DC fast charging station to meet it. There are generally two types. One is the DC high-power electric bus charging station recommended on this page, and the other is a pantograph charger.

The one on this page has wider versatility and cost-effectiveness and can charge two electric buses at the same time.

The pantograph charger must be OEM customized by the electric bus. The advantage is fully automatic charging without human intervention. The disadvantage is that it is very expensive, as well as being unavailable for other electric buses.

There are many factors affecting this, depending on your electric bus battery capacity, the maximum charging power accepted by the BMS, the power of the electric bus air-conditioner, and road conditions.

The cost of constructing an electric bus charging station varies depending on a number of factors. This includes the size of the charging station, equipment selection, site rental, 変圧器, construction costs, and government subsidies. Judging from our past experience, it should be at least $100,000 or more.

electric bus charging infrastructure, 電気バス充電ステーション, electric bus charging systems, 電気バスの充電, electric bus charging station cost

On April 7, TKT EVソリューション, a manufacturer of new energy vehicle chargers and air conditioners, established its new Hainan company.

TKTは、中国とインドの工場を持つ中国EV充電器メーカーです. 革新的なテクノロジーを競争力のある競争力としています.

EV充電器は精密デバイスです. EV DC充電電圧が正しく選択されていない場合, 多くの深刻な問題があります.