제품

배터리 열 관리 시스템은 전기 자동차 배터리 팩 온도를 적절한 범위 내로 유지하여 더 긴 주행 거리를 유지하고 배터리 수명을 연장합니다.. 우리는 또한 이를 BTMS 배터리, 배터리 냉각기 또는 배터리 팩 냉각 시스템이라고 부릅니다..

TKT Busthermo는 전기 버스 배터리용 열 관리 시스템 개발 전문 기업입니다., 전기 트럭 배터리, 전기 보트 배터리 및 전기 중장비 배터리. 냉난방 용량 3KW~10KW, 냉각수 냉각 및 PTC 가열을 통해 파워 배터리 팩의 온도를 최적의 범위로 유지합니다.. 이를 통해 전기 자동차는 더 긴 주행 거리와 서비스 수명을 달성할 수 있습니다..

이제 점점 더 많은 세계 최고 500 차량 제조업체는 TKT BTMS 시스템을 선택합니다., BYD와 같은, 타타 모터스, 스위치 이동성, 고양이 애벌레 그리고 다른 많은 사람들. 주로 우리 때문에:

1. BTMS 제품은 품질이 우수하며 시장 테스트를 통과했습니다. 10 연령.

2. 정밀한 온도 제어 (0.5℃), 가벼운 무게, 등..

3. 공정하고 매력적인 가격.

4. 추가적으로, 이는 고도로 맞춤화가 가능한 부품이며 고객의 사양에 정확히 맞춰 제작할 수 있습니다.. 냉각, 난방, 치수, 그리고 더 많은 것을 모두 사용자 정의할 수 있습니다.

TKT 제품에는 다양한 종류가 있습니다.. 에 오신 것을 환영합니다 문의하기 전문가의 조언을 구하거나 이메일:md@tkt-hvac.com.

맞춤형: 치수/냉각/가열

용량: 냉방 8-10KW/난방 6-10KW

흐름: 45-75L/분

전압: DC240V-DC750V

제품 모델: 10아르 자형 / 10EB용 CW

무게: 40KG

치수: 780*430*380mm (길이*세로*높이)

맞춤형: 치수/냉각/가열

용량: 냉각 5-6KW / 난방 3KW

흐름: 45-75L/분

전압: DC240V-DC750V

제품 모델: 5아르 자형 / 5EB용 CW

무게: 40KG / 32KG

치수: 750*550*293mm / 618*350*392.5mm (길이*세로*높이)

맞춤형: 치수/냉각/가열

추천: 냉방 3-4KW/난방 1-2KW

흐름: 45-75L/분

전압: DC240V-DC750V

제품 모델: 3아르 자형 / 3EB용 CW

무게: 25KG / 40KG

치수: 587*355*242mm / 447*310*583mm (길이*세로*높이)

맞춤형: 치수/냉각/가열

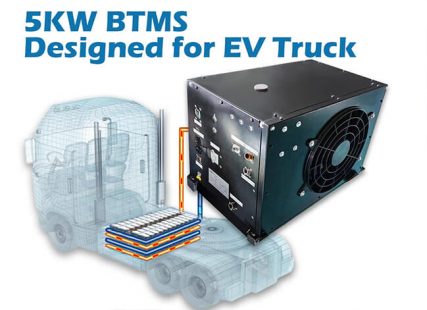

추천: 냉방 5KW/난방 3KW

흐름: 45-75L/분

전압: DC240V-DC750V

제품 모델: 5ET용 CW

무게: 32KG

치수: 618*350*392.5mm (길이*세로*높이)

맞춤형: 치수/냉각/가열

추천: 냉방 10KW/난방 6KW

흐름: 45-75L/분

전압: DC240V-DC750V

제품 모델: 10EHE용 CW

치수: 780*430*380mm (길이*세로*높이)

맞춤형: 치수/냉각/가열

추천: 냉방 5KW/난방 3KW

흐름: 45-75L/분

전압: DC240V-DC750V

제품 모델: 5EHE의 경우 R

무게: 40KG

치수: 750*550*293mm (길이*세로*높이)

맞춤형: 치수/냉각/가열

빠른 OEM/맞춤형 디자인 (1 월)

정밀한 온도 제어 (0.5 You.C)

잘못된 작동으로 인해 배터리 팩이 손상되지 않도록 제어할 수 있습니다.

혁신적인 기술: 전기 버스 A/C와 배터리 냉각 시스템을 병합하여 보다 포괄적인 EV 열 관리 시스템을 구성합니다..

✲ E-Bus A/C 냉각 용량: 42KW / 143K BTU

✲ BCS 냉각 용량: 8KW (난방 선택 사항)

✲ 신청: 순수 전기 버스

✲ 장점: 효율성 향상, 공간 절약, 덜 수리하다, 비용 절감

✲ 맞춤형: 치수/냉각/난방 등.

✲ 월드 탑 500 BYD/TATA 공급업체

✲ 오버 200,000 전 세계적으로 운영 중인 장치

✲ 10 R에서의 수년간의 경험&D와 디자인

✲ 인증: ISO 9001, IATF 16949, 등.

애플리케이션: 버스용 배터리 열관리 시스템 / 트럭 / 중장비 / 보트 등.

을 위한 10 연령, TKT는 다양한 OEM 고객의 요구에 따라 배터리 액체 냉각 시스템을 설계하고 제조했습니다.. 중국의 BYD와 같은, 유통버스, 킹 롱 버스, 등. 인도 타타모터스 등 해외시장 진출, 한국의 대우, 영국의 스위치 모빌리티, 등. TKT 배터리 열 관리 시스템 (비티엠에스) 고객 요구 사항에 따라 3-10KW 냉난방 기능 제공, 주변 온도가 60°C 또는 -20°C에 도달하더라도 다양한 상업용 차량의 요구 사항을 충족할 수 있습니다.. TKT는 지붕 장착형 배터리 냉각기도 만듭니다., 다양한 고객의 요구 사항에 따른 측면 장착형 배터리 냉각기 및 섀시 장착형 배터리 냉각기. TKT HVAC가 최고가 되었습니다 3 중국의 배터리 열 관리 시스템 제조업체 및 BTMS 공급업체.

“EV 배터리 열 관리 사례 연구 – Fortune을 위한 맞춤형 스토리 500” 읽으려면 클릭하세요 (적극 권장)

“행운 500 TATA 트럭 배터리 열관리 시스템 프로젝트” 읽으려면 클릭하세요

“트럭에 배터리 열 관리 초점 & 버스 요법. – 성숙한 고급 솔루션” 읽으려면 클릭하세요 (적극 권장)

“배터리 열 관리 맞춤화 솔루션 및 일반적인 맞춤화 방향” 읽으려면 클릭하세요

배터리 열 관리 시스템 (비티엠에스) 열전도 매체로 구성된 폐쇄 루프 온도 제어 시스템입니다., 측정 및 제어 장치, 및 온도 조절 장비. 배터리 시스템의 성능과 수명을 보장하기 위해 전원 배터리를 적절한 온도 범위 내에서 작동시켜 최상의 사용 상태를 유지합니다..

파워배터리는 전기차의 유일한 에너지원이자 전기차 성능에 영향을 미치는 중요한 지표다.. 충전 및 방전 과정에서 특정 열이 수반됩니다., 온도가 올라가게 되는 원인이 됩니다, 온도 상승은 배터리의 많은 작동 특성 매개변수에 영향을 미칩니다., 내부 저항과 같은, 전압, SOC, 사용 가능한 용량, 충전 및 방전 효율, 배터리 수명.

전원 배터리 열 효과 문제는 차량의 성능과 수명에 영향을 미칩니다.. 그러므로, 배터리 열관리는 배터리의 성능과 수명, 차량의 주행거리에 매우 중요합니다..

현재, 주로 공냉식으로 나누어집니다, 액체 냉각, 상변화 물질 냉각 및 침지 냉각. EV 배터리 냉각 시스템용, 액체 냉각은 가장 일반적이고 안정적인 솔루션입니다..

배터리 액체 냉각: 배터리는 냉각판을 통해 냉각수와 열을 교환합니다.. 냉각되거나 가열된 냉각수는 워터 펌프에 의해 열교환기로 보내집니다., 그 내부에서 열교환과 션트(shunting)가 이루어진다., 따라서 배터리를 위한 지속적이고 안정적인 액체 냉각 시스템을 형성합니다.. 선순환.

배터리 공기 냉각: 주로 공기 대류의 작동 원리를 활용하여 배터리실의 공기를 순환시킵니다.. 순환하는 공기가 배터리의 열을 제거합니다., 배터리의 온도를 낮춰주기 때문에. 단점은 냉각 효율이 상대적으로 낮다는 것입니다., 특히 고온 환경에서.

배터리 상변화 물질 (PCM) 냉각: PCM 소재는 주로 특정 주변 온도에서 고체와 액체 사이를 변환하는 데 사용됩니다., 이를 통해 배터리의 방열 및 발열 기능을 실현합니다.. 단점은 냉각 효율이 상대적으로 낮고 상변화 물질을 정기적으로 교체해야 한다는 점이다..

배터리 침수 냉각: 배터리를 특수 냉각수에 직접 넣어서, 액체의 대류 및 전도 효과는 배터리에서 발생하는 열을 냉각수로 빠르게 전달하는 데 사용됩니다., 이를 통해 배터리의 냉각 효과를 달성합니다.. 단점은 냉각수에 대한 요구 사항이 높고 후속 유지 관리 비용이 높다는 점입니다..

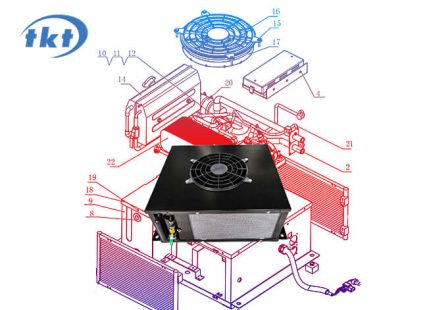

배터리 액체 냉각 시스템은 압축기로 구성됩니다., 콘덴서, 확장 밸브, 판형 열교환기, 전자 워터 펌프, PTC 액체 히터, 팽창 탱크, 및 전기 제어. 작동을 위해 배터리를 냉각해야 하는 경우, 배터리는 냉각판을 통해 냉각수와 열을 교환합니다., 가열된 냉각수는 전자 워터 펌프에 의해 열교환기로 보내집니다.. 열교환기의 한쪽으로 냉매가 유입되고 반대쪽으로 냉각수가 유입됩니다.. 열 교환기에서 두 사람이 열을 교환합니다., 냉매가 열을 빼앗아가도록 하기 위해. 차가운 냉각수는 열교환기에서 빠져나와 배터리로 유입됩니다.. 시스템은 순환을 형성합니다.; 배터리 온도가 낮아서 가열해야 할 때, 냉동 회로가 닫히고 PTC 액체 히터가 켜집니다.. 냉각수는 가열되어 배터리로 보내집니다., 배터리는 냉각판을 통해 가열됩니다.. 배터리 열관리는 냉동회로와 PTC 액체히터의 ON/OFF를 제어하여 배터리 내부 온도를 제어합니다..

간단히 말해서, BMS는 배터리 관리 시스템입니다., 더 넓은 범위를 포함하는. BTMS는 배터리 열 관리 시스템이며 BMS의 일부입니다.. BTMS의 자동화된 작동에는 BMS의 지침이 필요합니다.. 뇌와 팔다리의 관계로 이해될 수 있다.

수냉식 배터리, 액체 냉각 배터리 팩, 배터리의 열 관리, 배터리 팩 냉각 시스템, 배터리 냉각 장치, btms 배터리 열 관리 시스템, 리튬 배터리 냉각 시스템, 냉각 리튬 이온 배터리, 리튬 이온 배터리 열 관리, 배터리 온도 관리 시스템, 리튬 배터리 냉각, 전기차용 배터리 열관리 시스템, 배터리의 열 관리, 전기 자동차의 배터리 냉각 시스템, EV 배터리 냉각 시스템, 차량 배터리 열 관리 시스템, 전기차 배터리 냉각 시스템, 전기차 배터리 냉각 시스템, 고전압 배터리 냉각 시스템, 배터리 열 관리, EV 배터리 열 관리 시스템, 배터리 팩 열 관리, 액체 냉각 배터리.