✲ Disesuaikan: Dimensi/ Penyejukan/ Pemanasan dsb.

✲ Teratas Dunia 500 Pembekal BYD/ TATA

✲ Selesai 200,000 unit yang beroperasi di seluruh dunia

✲ 10 Tahun Pengalaman dalam R&D dan Reka Bentuk

✲ Pensijilan: ISO 9001, IATF 16949, dan lain-lain.

Permohonan: Sistem Pengurusan Terma Bateri untuk Bas / Lori / Alat Berat / bot dll.

The optimal operating temperature of the EV battery is 20° to 45°. Jika suhu ini melebihi, julat pandu dan hayat bateri akan jatuh secara mendadak. Apa lagi, ia juga boleh menjejaskan peralatan di sekeliling dan menyebabkan akibat pembakaran dan letupan. Jika bateri berada di bawah suhu ini, aktiviti tindak balas elektrokimia akan menjadi lemah dan prestasi bateri akan sangat berkurangan.

Battery thermal management system is a system specially designed to cool down power batteries. It is an indispensable component of commercial electric vehicles. TKT battery cooling system adopts liquid cooling and PTC for heating, which can steadily take away a large amount of heat generated by the battery. This is the most commonly used battery cooling method for electric buses, trak elektrik, peralatan berat elektrik, and electric boats.

Klik untuk mengetahui lebih lanjut tentang prinsip

TKT battery thermal management system has a wide range of solutions. The cooling capacity is from 3-10kw and the mounting positions are top mounted and side mounted. There is also the latest BTMS integrated system for bus air conditioning, which is an integrated solution for electric buses. TKT also supports OEM customization service. We can solve 99% of different customers’ needs.

Berjalan secara automatik untuk memastikan suhu bateri stabil

▲Lebih daripada 10 tahun bukti pasaran, habis 200,000 unit yang beroperasi di seluruh dunia, dengan kualiti dan prestasi yang diiktiraf secara meluas di seluruh dunia.

▲Reka bentuk Paten untuk membuat penyejukan/pemanasan yang lebih tinggi dengan berat yang kurang;

▲Aliran Penyejuk yang lebih besar untuk mengekalkan suhu bateri dalam suhu terpendek;

▲BOLEH Kawal untuk mengelakkan operasi yang salah untuk merosakkan pek bateri (Berjalan secara automatik untuk memastikan suhu bateri stabil);

▲Menggunakan bahagian elektrik IP67, seperti pemampat elektrik, pam air, penyambung dll;

▲Reka bentuk OEM/Tersuai yang pantas (1 bulan);

▲Kawalan Suhu Tepat (0.5 awak.C);

Pada masa lalu 10 tahun, TKT HVAC has developed rapidly and has become the top 3 battery thermal management system manufacturers in China. Dengan pengalaman OEM yang kaya, we have cooperated with many world-famous vehicle manufacturers. Seperti BYD, TATA motos, Tukar mobiliti, Daewoo, dan lain-lain. The cooperative projects include a variety of electric bus battery thermal management system, light truck battery thermal management system, heavy truck battery thermal management system, dan lain-lain.

“Kajian Kes Pengurusan Terma Bateri EV – Kisah Tersuai untuk Nasib 500” Klik untuk membaca (sangat disyorkan)

Ujian kenderaan sebenar, operasi yang stabil (Klik pada imej untuk membesarkan)

Selamat datang untuk menghubungi kami untuk nasihat model profesional. Sebagai tambahan, TKT provides OEM customization services, and vehicle manufacturers are welcome to consult.

| Sokongan Disesuaikan Perkhidmatan |

|

|

| Kapasiti | Menyejukkan: 8-10KW Pemanasan: 6-10KW (Pilihan) |

Menyejukkan: 5-6KW Pemanasan: 3KW (Pilihan) |

| Permohonan | 11-12M Electric Bus BTMS (DC240V-DC750V) |

8-10M Electric Bus BTMS (DC240V-DC750V) |

| produk Model |

10R/10CW for EBus View Page 10R/10CW |

5R/5CW for EBus View Page 5R/5CW |

| Sokongan Disesuaikan Perkhidmatan |

|

|

| Kapasiti | Menyejukkan: 3-4KW Pemanasan: 1-2KW (Pilihan) |

Menyejukkan: 5-6KW Pemanasan: 3KW (Pilihan) |

| Permohonan | 6-7M Electric Bus BTMS (DC240V-DC750V) |

Lori Elektrik BTMS (DC240V-DC750V) |

| produk Model |

3R/3CW for EBus View Page 3R/3CW |

5CW for ETruck View Page 5CW |

| Sokongan Disesuaikan Perkhidmatan |

|

|

| Kapasiti | Menyejukkan: 3-4KW Pemanasan: 1-2KW (Pilihan) |

BTMS Cooling: 8KW Bus A/C Cooling: 143K BTU |

| Permohonan | E-Alat Berat BTMS (DC240V-DC750V) |

E-bas a/c + BTMS (DC240V-DC750V) |

| produk Model |

3R untuk EHE View Page 3R |

View Page Integrated System |

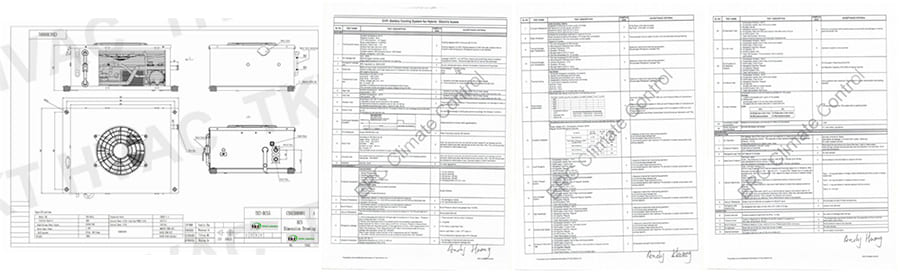

Hubungi kami untuk Imej Resolusi Tinggi

1. Battery type and specifications: Different battery application scenarios have different requirements for battery thermal management system. Sebagai contoh, if it is a power battery and applied to an electric bus, its battery voltage is usually between 280v-750v. When an electric bus is running, the battery produces a lot of heat, which requires a battery liquid cooling system.

2. EV Reserve space: When different vehicle manufacturers design new vehicles, the design space of each part is planned. Sebagai contoh, because electric trucks have boxes, we usually recommend designing the truck battery thermal management system (BTMS) on the outside of the truck and adopting a side-mounted installation solution. The advantage of this is that it is conducive to the release of heat dissipation performance and the battery cooling efficiency is high. Sudah tentu, we also have other truck battery cooling solutions that can solve 95% of truck battery cooling needs. For another example, the overall space of electric heavy machinery is small, so there are strict requirements on the size of the battery thermal management system. We have split battery cooling solutions and also provide customized services, so we can perfectly solve the needs of battery thermal management system of different sizes.

3. Quality and reliability: The battery thermal management system (BTMS) is very important for electric vehicles. It can not only ensure vehicle safety but also reduce vehicle operating costs. A high-quality cooling system can greatly improve battery life and vehicle range, thereby reducing battery replacement costs and vehicle charging costs. Therefore it is very important to choose a good battery thermal management system. TKT BTMS products have been supplied to Fortune 500 syarikat, passed their strict inspections, and have been in actual vehicle operation for more than 5 tahun. Only practice can tell whether a product is good or not. Five years of stable operation is the best proof. TKT has rich experience in cooperation with OEM vehicle manufacturers, seperti BYD project, TATA motors project, Switch mobility project, dan lain-lain.

Gegelung pemeluwap, kipas kondenser, tangki air, pam air, penukar haba, pemampat elektrik, panel kawalan, modul BOLEH, injap pengembangan, dan lain-lain.

The condenser system cools down the coolant and the water pump will run the coolant through the BTMS and the battery structure system to release the heat generated by the battery pack.

Battery thermal management system is mainly divided into battery air cooling, penyejukan cecair bateri, phase change material cooling, and battery immersion cooling. Different cooling methods need to be selected based on scenario judgment. For commercial electric vehicles, because the battery capacity of electric vehicles is relatively large, they are all high-voltage power batteries, so they release a lot of heat. Now the most cost-effective and stable program is battery liquid cooling.

The function of the battery thermal management system is to adjust the temperature of the battery in real time and maintain the battery operating within the optimal temperature range to ensure battery performance, life and safety. Mainly speaking, it is divided into the following situations.

1. Prevent overheating: When the battery temperature is too high, the battery performance will be affected and may even malfunction. The battery thermal management system can reduce the battery temperature in time through heat dissipation and other methods to prevent the battery from overheating.

2. Prevent overcooling: In low-temperature environments, battery performance will also be affected and may even fail to work properly. The battery thermal management system can promptly increase the battery temperature through heating and other methods to prevent the battery from overcooling.

3. Maintain battery temperature stability: During vehicle driving, the battery temperature will continue to change. If the temperature fluctuation is too large, it will have a negative impact on battery performance. The battery thermal management system can keep the battery temperature stable by controlling coolant flow and other methods.

4. Improve battery life: By controlling the battery temperature within the optimal range, the battery life can be extended. Reduce the number of replacements and reduce maintenance costs.

Teknologi penyejukan bateri lebih menuntut untuk reka bentuk bas elektrik dan trak elektrik, yang telah diusahakan oleh TKT sejak itu 2012.

Penyelesaian paling berkesan untuk meningkatkan jarak pemanduan tanpa menambah bilangan bateri ialah sistem pengurusan haba bateri tersuai.

Kes Pengurusan Terma Bateri EV – Disesuaikan untuk Fortune 500. BTMS TKT mempunyai 10 tahun pengalaman reka bentuk.