product

Battery thermal management system keep electric vehicle battery pack temperatures within the right range to maintain their longer driving range and extend battery life. We also call it BTMS Battery or Battery Chiller or Battery Pack Cooling System.

TKT Busthermo specializes in developing thermal management systems for electric bus batteries, electric truck batteries, electric boat batteries and electric heavy equipment batteries. With a cooling/heating capacity of 3KW-10KW, they keep the temperature of the power battery pack in the optimal range by means of coolant cooling and PTC heating. This allows electric vehicles to achieve longer range and service life.

Now more and more world top 500 vehicle manufacturers choose TKT BTMS system, such as BYD, Tata Motors, Switch Mobility, CAT Caterpillar and many others. Mainly because of us:

1. BTMS products are of good quality and have passed the market test for 10 years.

2. Precise temperature control (0.5℃), light weight, etc..

3. Fair and attractive price.

4. Additionally, This is a highly customizable part and we can make it exactly to the customer’s specifications. Cooling, heating, dimensions, and more can all be customized.

Customized: Dimension/ Cooling/ Heating

Capacity: Cooling 8-10KW/ Heating 6-10KW

Flow: 45-75L/min

Voltage: DC240V-DC750V

Product Model: 10R / 10CW for EB

Weight: 40KG

Dimension: 780*430*380mm (L*W*H)

Customized: Dimension/ Cooling/ Heating

Capacity: Cooling 5-6KW / Heating 3KW

Flow: 45-75L/min

Voltage: DC240V-DC750V

Product Model: 5R / 5CW for EB

Weight: 40KG / 32KG

Dimension: 750*550*293mm / 618*350*392.5mm (L*W*H)

Customized: Dimension/ Cooling/ Heating

Recommended: Cooling 3-4KW/ Heating 1-2KW

Flow: 45-75L/min

Voltage: DC240V-DC750V

Product Model: 3R / 3CW for EB

Weight: 25KG / 40KG

Dimension: 587*355*242mm / 447*310*583mm (L*W*H)

Customized: Dimension/ Cooling/ Heating

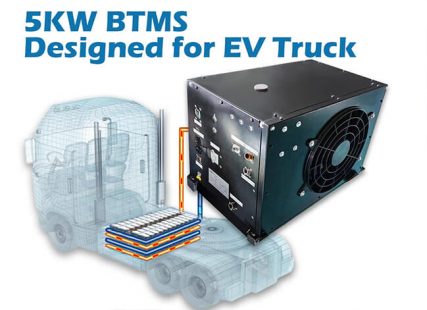

Recommended: Cooling 5KW/ Heating 3KW

Flow: 45-75L/min

Voltage: DC240V-DC750V

Product Model: 5CW for ET

Weight: 32KG

Dimension: 618*350*392.5mm (L*W*H)

Customized: Dimension/ Cooling/ Heating

Recommended: Cooling 10KW/ Heating 6KW

Flow: 45-75L/min

Voltage: DC240V-DC750V

Product Model: 10CW for EHE

Dimension: 780*430*380mm (L*W*H)

Customized: Dimension/ Cooling/ Heating

Recommended: Cooling 5KW/ Heating 3KW

Flow: 45-75L/min

Voltage: DC240V-DC750V

Product Model: 5R for EHE

Weight: 40KG

Dimension: 750*550*293mm (L*W*H)

Customized: Dimension/ Cooling/ Heating

Fast OEM/Customized Design (1 month)

Precise Temperature Control (0.5 Deg.C)

CAN Control to avoid the wrong operation to damage battery pack

Customized: Dimension / Cooling / Heating

Fast OEM / Customized Design (1 month)

Innovative Technology: We merge the electric bus A/C and battery cooling systems to form a more comprehensive ev thermal management system.

✲ E-Bus A/C Cooling Capacity: 42KW / 143K BTU

✲ BCS Cooling Capacity: 8KW (Heating optional)

✲ Application: Pure Electric Bus

✲ Advantages: Improve Efficiency, Save Space, Repair Less, Save Costs

✲ Customized: Dimension/ Cooling/ Heating etc.

✲ World Top 500 BYD/ TATA Supplier

✲ Over 200,000 units in operation worldwide

✲ 10 Years of Experience in R&D and Design

✲ Certifications: ISO 9001, IATF 16949, etc.

Application: Battery Thermal Management System for Bus / Truck / Heavy Equipment / boat etc.

For 10 years, TKT has designed and manufactured battery liquid cooling systems according to the needs of different OEM customers. Such as China’s BYD, Yutong Bus, King Long Bus, etc. and overseas markets such as India’s Tata Motors, South Korea’s Daewoo, and the UK’s Switch Mobility, etc. TKT Battery Thermal Management System (BTMS) provides 3-10KW cooling and heating capabilities according to customer requirements, and can meet the requirements of different commercial vehicles even if the ambient temperature reaches 60°C or -20°C. TKT also makes roof-mounted Battery Chiller, side-mounted Battery Chiller and chassis-mounted Battery Chiller according to the requirements of different customers. TKT HVAC has become the top 3 battery thermal management system manufacturers and BTMS suppliers in China.

“EV Battery Thermal Management Case Study – A Customized Story for Fortune 500” Click to read (highly recommended)

Battery Pack Cooling System Related News

Battery Pack Cooling System Related News“Fortune 500 TATA Truck Battery Thermal Management System Project” Click to read

“Battery Thermal Management Focus On Truck & Bus ect. – Mature Advanced Solutions” Click to read (highly recommended)

“Battery thermal management customization solutions and common customization directions” Click to read

Battery thermal management system (BTMS) is a closed -loop temperature control system composed of heat -conducting medium, measurement and control unit, and temperature control equipment. It makes power battery work within the appropriate temperature range to maintain its best use state to ensure the performance and life of the battery system.

Power battery is the only source of energy for electric vehicles and an important indicator affecting the performance of electric vehicles. It will accompany a certain heat during the charging and discharge process, which will cause the temperature to rise, and the increase in temperature will affect many working characteristics parameters of the battery, such as internal resistance, voltage, SOC, available capacity, charging and discharge efficiency, and battery life.

The problem of power battery thermal effects will affect the performance and cycle life of the vehicle. Therefore, the battery thermal management is very important for the performance and life of the battery and the mileage of the vehicle.

At present, it is mainly divided into air cooling, liquid cooling, phase change material cooling and immersion cooling. For EV battery cooling system, liquid cooling is the most common and stable solution.

Battery liquid cooling: The battery exchanges heat with the coolant through the cooling plate. The cooled or heated coolant is sent into the heat exchanger by a water pump, and heat exchange and shunting are performed inside it, thus forming a continuous and stable liquid cooling system for battery. A virtuous cycle.

Battery air cooling: Mainly utilizes the working principle of air convection to circulate the air in the battery compartment. The circulating air removes heat from the battery, thereby lowering the temperature of the battery. The disadvantage is that the cooling efficiency is relatively low, especially in high temperature environments.

Battery phase change material (PCM) cooling: PCM materials are mainly used to transform between solid and liquid at specific ambient temperatures, thereby realizing the heat dissipation and heating functions of the battery. The disadvantages are relatively low cooling efficiency and the need for regular replacement of phase change materials.

Battery immersion cooling: By placing the battery directly in a special coolant, the convection and conduction effects of the liquid are used to quickly transfer the heat generated by the battery to the coolant, thereby achieving the cooling effect of the battery. The disadvantages are higher requirements for coolant and high subsequent maintenance costs.

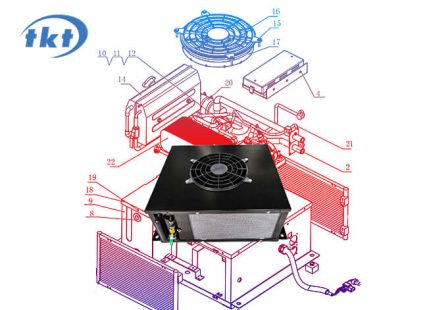

The battery liquid cooling system consists of a compressor, condenser, expansion valve, plate heat exchanger, electronic water pump, PTC liquid heater, expansion tank, and electrical control. When the battery needs to be cooled for operation, the battery exchanges heat with the coolant through the cooling plate, and the heated coolant is sent into the heat exchanger by the electronic water pump. The refrigerant is introduced into one side of the heat exchanger and the coolant is introduced into the other side. The two exchange heat in the heat exchanger, so that the heat is taken away by the refrigerant. The cold coolant flows out of the heat exchanger and then flows into the battery. The system forms a cycle; when the battery is at low temperature and needs to be heated, the refrigeration circuit is closed and the PTC liquid heater is turned on. The coolant is heated and sent into the battery, and the battery is heated through the cooling plate. The battery thermal management controls the internal temperature of the battery by controlling the on and off of the refrigeration circuit and the PTC liquid heater.

Simply put, BMS is a battery management system, which includes a wider range. BTMS is the battery thermal management system and is part of the BMS. The automated operation of BTMS requires instructions from BMS. It can be understood as the relationship between the brain and the limbs.

water cooled battery, liquid cooled battery pack, thermal management of batteries, cooling system for battery pack, battery cooling unit, btms battery thermal management system, lithium battery cooling system, cooling lithium ion battery, lithium ion battery thermal management, battery temperature management system, lithium battery cooling, battery thermal management system for electric vehicles, thermal management of battery, battery cooling system in electric vehicle, ev battery cooling systems, vehicle battery thermal management system, electric vehicle battery cooling system, electric vehicle battery cooling system, high voltage battery cooling system, batterie thermomanagement, ev battery thermal management system, battery pack thermal management, liquid cooling battery.