product

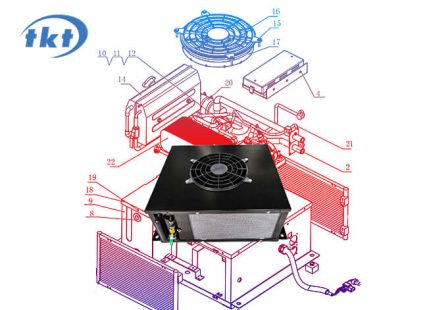

Battery Chillers is to reduce the temperature of the battery in the operation. A running battery, if kept within a reasonable temperature range, will result in more power and driven distance for electric equipment and longer battery life. We also call it battery thermal management system or BCS, BTMS.

TKT started designing and manufacturing Battery Chillers in 2012 for various electric equipment. TKT has developed a series of products to solve the problem of battery temperature. These products offer a variety of outstanding advantages, such as achieving precise temperature control (0.5°C), product lightweighting studies, and products that have passed 10 years of market testing, among other reasons.

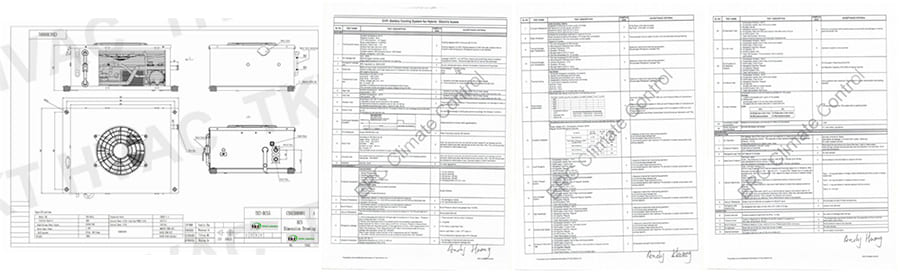

Note: This is a highly customizable part and we can manufacture it exactly to the customer’s specifications. Cooling, heating, dimensions, etc. can all be customized.

There are many types of TKT products. Welcome to contact us for expert advice or Email:md@tkt-hvac.com.

Customized: Dimension/ Cooling/ Heating

Fast OEM/Customized Design (1 month)

Precise Temperature Control (0.5 Deg.C)

CAN Control to avoid the wrong operation to damage battery pack

Customized: Dimension / Cooling / Heating

Fast OEM / Customized Design (1 month)

Innovative Technology: We merge the electric bus A/C and battery cooling systems to form a more comprehensive ev thermal management system.

✲ E-Bus A/C Cooling Capacity: 42KW / 143K BTU

✲ BCS Cooling Capacity: 8KW (Heating optional)

✲ Application: Pure Electric Bus

✲ Advantages: Improve Efficiency, Save Space, Repair Less, Save Costs

✲ Customized: Dimension/ Cooling/ Heating etc.

✲ World Top 500 BYD/ TATA Supplier

✲ Over 200,000 units in operation worldwide

✲ 10 Years of Experience in R&D and Design

✲ Certifications: ISO 9001, IATF 16949, etc.

Application: Battery Thermal Management System for Bus / Truck / Heavy Equipment / boat etc.

Over the past 10 years, TKT has designed and manufactured Battery Pack Cooling System according to the requirements of different OEM customers, such as BYD, Yutong and Golden Dragon in China, and TATA Motors in India, Daewoo in Korea and other overseas markets. The cooling capacity and heating capacity of Battery Thermal Management System(BTMS) ranges from 3-10KW according to customer’s requirements, which can meet the requirements of different commercial vehicles even if the ambient temperature reaches 60 degrees C or -20 degrees C. TKT also makes roof-mounted Battery Chiller, side-mounted Battery Chiller and chassis-mounted Battery Chiller according to the requirements of different customers.

“EV Battery Thermal Management Case Study – A Customized Story for Fortune 500” Click to read (highly recommended)

Contact us for High Resolution Images

“Fortune 500 TATA Truck Battery Thermal Management System Project” Click to read

“Battery Chiller Focus On Truck & Bus ect. – Mature Advanced Solutions” Click to read (highly recommended)

“Battery Chiller customization solutions and common customization directions” Click to read

Professional manufacturer & supplier of vehicle air conditioning system and battery thermal management system. Both technical strength and output are in a leading position. TKT has 25 engineers with master and doctorate degrees, 480 workers with 4-8 years of assembly experience, and 85 countries to provide you with perfect after-sales service. The main products have CE, EMI/EMC certification.