TKT HVAC is the top bus air conditioner manufacturer in China. It is also the bus air conditioning supplier of BYD and TATA, which are top 500 companies.

✲ Factory Price, High-Quality!!

✲ Certifications: ISO 9001, IATF 16949, etc.

Application: AC for Electric Bus, Diesel Bus, Coach, Van, etc.

TKT HVAC is the top 3 bus air conditioner manufacturers and bus AC suppliers in China. TKT has a variety of air conditioning solutions that can be applied to electric buses, diesel buses, shuttle buses, school buses, coaches, airport shuttles, etc. Our solutions can meet 99% of customer needs, while also providing more professional customized services. As bus ac manufacturers established for more than 20 years, we have our own factory in India, we are also a famous bus air conditioner manufacturers in India.

Bus air conditioning is mainly divided into two types, one is electric bus air conditioner and the other is diesel bus air conditioner. Air conditioner for electric bus is only suitable for pure electric bus and is powered by power batteries. This type of air conditioner requires a very high voltage, generally between 280-750v.

Air conditioner for diesel bus is suitable for traditional diesel bus and is mainly driven by the engine. This type of air conditioner will not be able to operate the air conditioner when the bus is stopped. Of course, TKT has sub engine bus air conditioner to solve this problem and ensure that the diesel buses have uninterrupted air conditioning when parked.

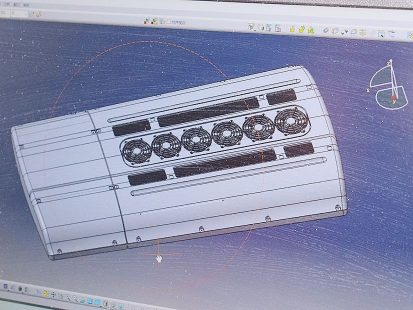

TKT supports OEM/ODM services. Welcome to consult.

As a veteran bus air conditioner manufacturer, we are fully aware that you get what you pay for. TKT utilizes quality components to ensure that our products have superior performance and a longer lifespan. When you choose TKT Busthermo, you’re getting a reliable, top-of-the-line cooling solution.

✔ Patent System Design to Guarantee Super Cooling for Tropical Climate;

✔ Inner Screw Copper Tube & Hydrophilic Alu. To Guarantee 12-18 Years Life Time;

✔ Adopting World Top Brand Components to Lower Life Cycle Cost;

✔ Easy Installation, Operation & Service;

✔ Fresh Air Available;

✔ OEM/Customized System/More Requirement Acceptable;

Learn More Bus AC Advantages in Detail

As a leading bus air conditioner manufacturers in China, TKT Busthermo has supplied to BYD, TATA motors, Marco Polo, Yutong Bus, Isuzu, Daewoo, Beiqi Foton Bus, and other global vehicle manufacturers.TKT has rich experience in OEM manufacturing and service. Air-conditioning products have passed the strict quality inspection of the world’s top 500 companies.

Click for More Cases (Load HD Pictures, Wait Patiently)

| Click on image to enlarge |  |

|

| Cooling Capacity |

42KW (143K BTU) Heating optional |

55KW (187K BTU) Heating optional |

| Application | 10M-12M E-Bus DC280-750V | Double Decker Bus DC450-750V |

| Product Model |

420E View Page 420E |

550ED View Page 550ED |

| Click on image to enlarge |  |

|

| Cooling Capacity |

16 KW (54K BTU) Heating optional |

26 KW (88K BTU) Heating optional |

| Application | 6M-7M E-Bus DC280-750V | 9M-10M E-Bus DC450-750V |

| Product Model |

160E View Page 160E |

260E View Page 260E |

Application: AC for Diesel Bus, Electric Bus, Coach, Van, etc. Contact us for professional model advice.

| Click on image to enlarge |  |

|

| Cooling Capacity |

40 KW (136K BTU) Heating optional |

38 KW (129K BTU) Heating optional |

| Application | 13M-14M Diesel Bus | 12M-13M Diesel Bus |

| Product Model |

400B View Page 400B |

380B View Page 380B |

| Click on image to enlarge |  |

|

| Cooling Capacity |

34 KW (115K BTU) Heating optional |

26 KW (88K BTU) Heating optional |

| Application | 11M-12M Diesel Bus | 9M-10M Diesel Bus |

| Product Model |

340B View Page 340B |

260M View Page 260M |

| Click on image to enlarge |  |

|

| Cooling Capacity |

20 KW (68K BTU) Heating optional |

18 KW (61K BTU) Heating optional |

| Application | 7M-8M Diesel Bus | 6M-7M Diesel Bus |

| Product Model |

200M View Page 200M |

180M View Page 180M |

| Click on image to enlarge |  |

|

| Cooling Capacity |

14 KW (47K BTU) Heating optional |

12 KW (40K BTU) Heating optional |

| Application | Seats<28 Van | Seats<18 Van |

| Product Model |

140V View Page 140V |

120V View Page 120V |

| Click on image to enlarge |  |

|

| Cooling Capacity |

5 KW (17K BTU) |

16~55 KW (54~187K BTU) Heating optional |

| Application | Mini Bus | Pure E-Bus |

| Product Model |

50ER View Page 50ER |

160E~550ED View Page Electric Bus AC |

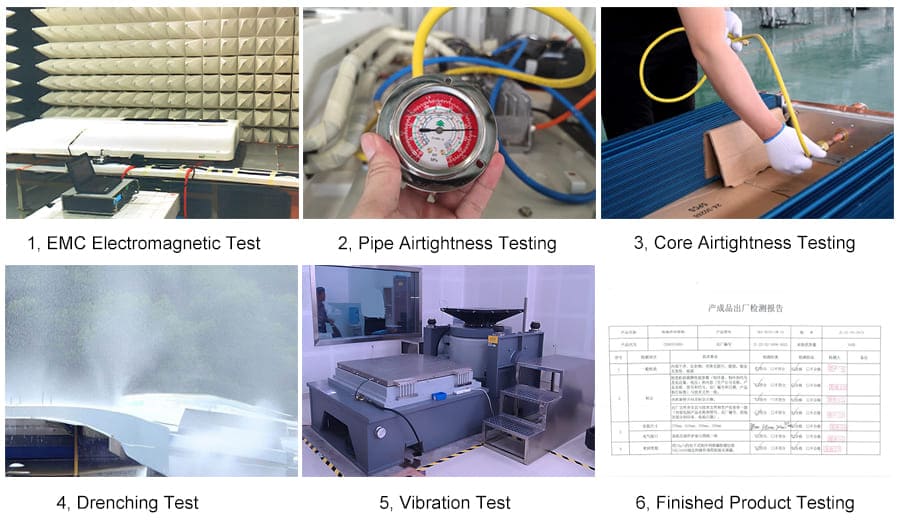

EMC Electromagnetic Test, Pipe Airtightness Testing, Core Airtightness Testing, Drenching Test, Vibration Test, Finished Product Testing. (Click here to view bus air conditioner quality Inspection details)

We have many close partners around the world. You are welcome to come to our TKT factory for on-site inspection and establish a close cooperative relationship with us to achieve a win-win situation. And work together for the sustainable development and environmental protection of the world. (Click to learn more benefits)

1. Why Choose us?

A. Reliable quality and competitive Price

B: Professional and well trained sales, and Technical support

C: Flexible payment terms

2. What is your Warranty Policy?

Firstly, we provide 18 months warranty from the date of delivery. Free spare parts will be provided if the parts defective for quality reason during the warranty period. But videos and fault description will be need for engineer double check first! Damage or defective caused by improper use not covered by warranty.

TKT HVAC was founded in 1998. So far, it has obtained many quality certificates such as ISO9001:2015, IATF16969:2016, CE, EMI/EMC, etc. And owns more than 100 related patents.

Typically 7-10 days if in stock.

If there is no stock, it is usually in 3 weeks. Of course, the specific situation depends on the order quantity and the task of our factory.

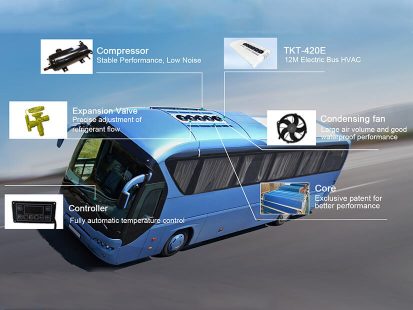

Bus air conditioner is an air conditioning system used in bus. It provides a comfortable travelling environment for passengers by regulating air temperature, humidity and flow rate. A bus air-conditioning system consists of major components such as compressor, condenser, evaporator, expansion valve and fan. The compressor is responsible for compressing the refrigerant and raising its temperature and pressure; the condenser dissipates the high temperature and pressure refrigerant through the radiator, cooling it and condensing it into a high-pressure liquid; the expansion valve controls the flow rate and pressure of the refrigerant so that it enters the evaporator; and the fan is used to circulate the air and increase the air flow rate.

The operation process of the bus air conditioner system is as follows: the compressor draws in the low-temperature and low-pressure refrigerant gas and converts it into a high-temperature and high-pressure gas through compression; subsequently, the high-temperature and high-pressure gas passes through the condenser to dissipate the heat, and condenses into a high-pressure liquid through cooling; the high-pressure liquid then enters into the evaporator through the expansion valve, and the low-pressure liquid in the evaporator flows through the pipeline, and the contact with the outside air occurs with heat transfer, and the refrigerant absorbs heat and evaporates into a gas, making the internal temperature of the evaporator rise. The refrigerant absorbs heat and evaporates into gas, which lowers the temperature inside the evaporator, thus achieving the cooling effect.

Bus air conditioning is applicable to a wide range of vehicle types, and the need to install an air-conditioning system is mainly determined by their usage, passenger carrying capacity and operating environment.

City Buses: As the main mode of public transport in cities, city buses usually need to carry a large number of passengers. Installing air-conditioning systems in these vehicles can ensure that passengers can enjoy a comfortable travelling environment even in the hot summer months.

Long-distance buses: Long-distance buses are often required to travel on motorways or inter-regional routes, where passengers need to spend long periods of time in the vehicle. Therefore, it is necessary to install air-conditioning systems for long-distance buses.

Tourist buses: Tourist buses are mainly used for sightseeing tours and usually carry tourists on long journeys. Installing high quality air conditioning systems in these vehicles can enhance the travelling experience.

Double-decker buses: Due to their special design and large passenger capacity, double-decker buses require an air-conditioning system that can evenly distribute cool air and provide a comfortable environment.

In general, bus air conditioning systems are suitable for models that need to carry a large number of passengers and run for long hours. These systems can be customised and optimised to meet the specific needs of different models to ensure passenger comfort and satisfaction.

The refrigerant used in bus air conditioner, R-134A, is one of the most common and widely used refrigerants.

R-134A is now internationally recognised as the main refrigerant workhorse replacing R-12, and is used not only in bus air conditioning but also in a wide range of commercial and industrial refrigeration systems.

R-407C is the refrigerant of choice for air conditioning in electric bus. In addition, refrigerants such as R-22 and R-410A may be used in some specific applications or in bus air conditioning system of specific manufacturers.

1. Check the air-conditioning pipework and connecting parts: After prolonged use, the air-conditioning pipework and connecting parts may become loose or cracked, resulting in poor cooling effect. Therefore, it is necessary to check the status of these parts regularly.

2. Check refrigerant pressure: Refrigerant is the core component of the air conditioning cooling process. Use a refrigerant pressure checking tool to check the refrigerant pressure and determine if the pressure is normal based on the standard values provided by the manufacturer.

3. Clean the evaporator and condenser: the cleanliness of these components directly affects the cooling effect. The surfaces of the evaporator and condenser should be cleaned regularly to ensure that they dissipate heat well.

4. Check the compressor and fan: regularly check the quality of the compressor and fan. They will affect the refrigeration effect.

TKT bus air conditioners are used in a wide range of scenarios, including school bus air conditioner, carrier bus air conditioner, denso bus air conditioner, shuttle bus air conditioner, tata bus air conditioner, 24v bus air conditioner, etc.

It introduces in detail the key parts of the bus aircon and the working principle of key part. Easy to understand and very professional.

TKT has a wealth of bus air conditioning unit solutions. This article introduces many basic knowledge and installation steps of bus A/C.

AC combine chiller project is an innovative design that integrates EV battery cooling system and electric bus air conditioning.