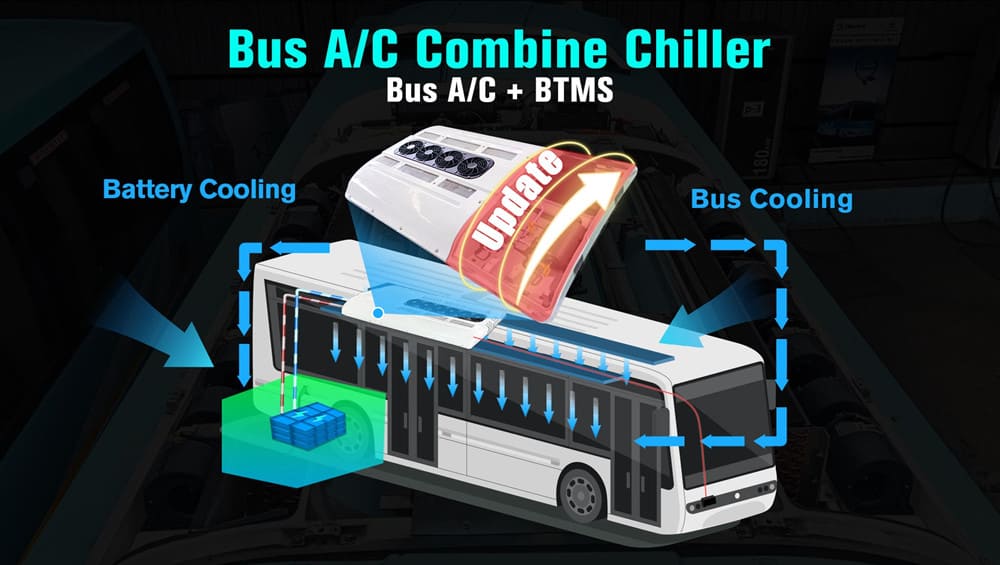

TKT EV thermal management system uses innovative technology to integrate electric bus A/C and BTMS. It can also be called vehicle thermal management system (VTMS).

1. E-Bus A/C Cooling Capacity: 42KW / 143K BTU

2. BTMS Cooling Capacity: 8KW (Heating optional)

3. Application: Pure Electric Bus

4. Advantages: Improve Efficiency, Save Space, Repair Less, Save Costs

The integration of the battery cooling system (BCS) with the air conditioning of the bus is an intelligent innovation. This is thanks to the hard research of TKT engineers. In a later article, I will call this integrated system the EV thermal management system. Some regional customers also call it A/C Combine Chiller. Its emergence will bring many benefits.

First, let me briefly introduce two independent products.

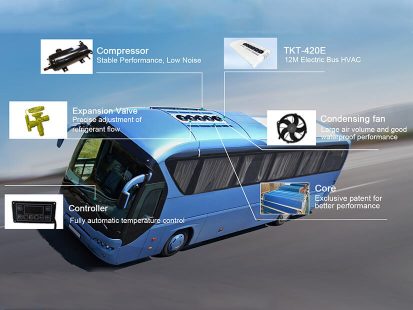

What is electric bus air conditioner? It mainly serves passengers. Cool down passengers and ensure a comfortable ride. It is one of the main power-consuming equipment of electric buses. Therefore, reducing the energy consumption of electric bus air conditioners and improving the efficiency of electric bus air conditioners can significantly improve the competitiveness of electric buses.

What is a battery cooling system? It mainly serves the power battery of electric vehicles. Through cooling or heating (TKT use liquid cooling), the battery is ensured to work within a suitable temperature range, thereby improving the efficiency, lifespan and safety of the battery. As the power source of electric buses, the efficiency of power batteries determines the competitiveness of electric buses.

| Model | TKT-420E | |

| Cooling | 42 KW/(143K BTU) | |

| Heating | Heat pump is optional | |

| Control way | Digital control panel + CAN Control(optional) | |

| Application | 10M-12M EV Bus | |

| Refrigerant | R407C | |

| Compressor Voltage/Power Supply | DC450-750 V | |

| Control Voltage/Power Supply | DC24 V/10 A | |

| Electric bus A/C Compressor | Japan SANYO Brand Vortex Compressor (74.4 cc/r) | |

| Condenser | Coil type | Copper Tube and Aluminum Fin Structure |

| Fan Air Volume | 9000 m³/h (6 Fans) | |

| Evaporator | Coil type | Copper Tube and Aluminum Fin Structure |

| Blower Air Volume | 14400 m³/h (9 Blowers) | |

| Dimension | 3200*1830*250 mm | |

| Product Model | 10R / 10CW |

| Application | 11-12M Electric Bus BCS |

| Capacity | Cooling: 8KW~10KW |

| Heating: 6-10KW (Optional) | |

| Customized | Dimension/ |

| Cooling/ | |

| Heating ect. | |

| Voltage | 240-750V |

| Flow | 45-75L/min |

| Weight | 40 KG |

| Dimension (L*W*H) | 780*430*380mm |

| Installation Location | Roof/ Side/ Rear Mount |

| Control Power (V/A) | DC24V/10A or DC12V/20A |

First of all, this integrated system improves cooling efficiency and reduces energy waste. One system can complete the cooling of two important areas. It can ensure that the battery works within the most suitable temperature range and extend the life of the battery. At the same time, it provides the required cooling and heating to the interior of the bus. Such an EV thermal management system means longer battery range, more reliable performance, and a better passenger experience.

In addition, integrating BCS and bus air conditioning can reduce system complexity. The integrated design reduces the number of parts and improves the reliability of the entire system. This design also reduces maintenance costs and the probability of operating system errors. Overall, it reduces manufacturing costs, making electric buses more competitive.

In summary, EV thermal management system brings higher efficiency, lower cost and better passenger experience to electric buses. This system will be one of the important components in the future passenger vehicle transportation system. We will also continue to work hard to promote the development of electric buses.

The development of this integrated system mainly stems from the cooperation with BYD (BYD, a Fortune 500 company and a famous vehicle manufacturer). The first cooperation project between TKT and BYD is pure electric bus air conditioning. TKT customized electric bus air conditioners for two new models of BYD. The customized air conditioners of these two new models are mainly improved on the basis of 260E and 420E. Please click to learn more about specific details.

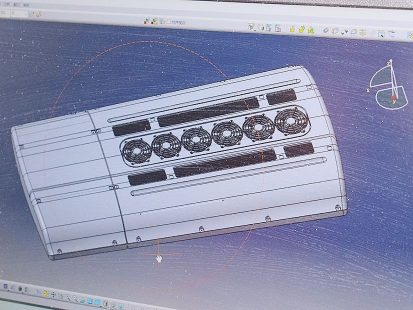

After the successful cooperation, TKT’s product strength, design capabilities, and manufacturing capabilities have been trusted by BYD, a Fortune 500 company. Therefore, the second cooperation was the research and development of this integrated system. They held multiple video conferences with each other to discuss technical details, confirm design ideas and plans, etc. TKT engineers have perfected all the details of this integrated system after many revisions to the design drawings and experimental simulations.

After the successful cooperation, TKT’s product strength, design capabilities, and manufacturing capabilities have been trusted by BYD, a Fortune 500 company. Therefore, the second cooperation was the research and development of this integrated system. They held multiple video conferences with each other to discuss technical details, confirm design ideas and plans, etc. TKT engineers have perfected all the details of this integrated system after many revisions to the design drawings and experimental simulations.

Subsequently, senior engineers and factory technical workers participated in the manufacturing process. They perfected the adjustment of assembly details, checked whether the control system was smooth, and tested the real cooling effect.

In the end, TKT relied on its strong strength to live up to expectations and complete this product innovation.

It introduces in detail the key parts of the bus aircon and the working principle of key part. Easy to understand and very professional.

AC combine chiller project is an innovative design that integrates EV battery cooling system and electric bus air conditioning.

The article is to introduce the principles and installation requirements of the battery thermal management system (BTMS battery).