Carregadores EV

Sistema de gerenciamento térmico de bateria

Ar condicionado elétrico

Ar condicionado acionado por motor

✲ Personalizado: Dimensão/ resfriamento/ aquecimento etc.

✲ Top mundial 500 Fornecedor BYD/ TATA

✲ acima 200,000 unidades em operação em todo o mundo

✲ 10 Anos de experiência em r&D e design

✲ Certificações: ISO 9001, IATF 16949, etc..

Aplicativo: Sistema de gerenciamento térmico da bateria para barramento / Caminhão / Equipamento pesado / barco etc..

A temperatura operacional ideal da bateria EV é de 20 ° a 45 °. Se esta temperatura for excedida, a autonomia e a vida útil da bateria cairão drasticamente. Além do mais, também pode afetar o equipamento circundante e causar as consequências de combustão e explosão. Se a bateria estiver abaixo desta temperatura, sua atividade de reação eletroquímica ficará fraca e o desempenho da bateria será bastante reduzido.

O sistema de gerenciamento térmico da bateria é um sistema especialmente projetado para resfriar as baterias de energia. É um componente indispensável de veículos elétricos comerciais. O sistema de resfriamento de bateria TKT adota resfriamento líquido e PTC para aquecimento, que podem tirar constantemente uma grande quantidade de calor gerado pela bateria. Este é o método de resfriamento de bateria mais comumente usado para ônibus elétricos, caminhões elétricos, equipamento elétrico pesado, e barcos elétricos.

Clique para saber mais sobre o princípio

O sistema de gerenciamento térmico da bateria TKT possui uma ampla gama de soluções. A capacidade de resfriamento é de 3-10kW e as posições de montagem são montadas no topo e montadas laterais. Há também o último BTMS Integrated System para ar condicionado de barramento, que é uma solução integrada para ônibus elétricos. O TKT também suporta o serviço de personalização OEM. Podemos resolver 99% de diferentes clientes’ precisa.

Funciona automaticamente para manter a temperatura da bateria estável

▲Mais do que 10 anos de prova de mercado, sobre 200,000 unidades em operação em todo o mundo, com qualidade e desempenho amplamente reconhecidos mundialmente.

▲ Design de patente para maior resfriamento/aquecimento com menos peso;

▲ Maior fluxo de refrigerante para manter a temperatura da bateria na temperatura mais baixa;

▲ Controle CAN para evitar operação errada e danificar a bateria (Funciona automaticamente para manter a temperatura da bateria estável);

▲ Adote peças elétricas IP67, como compressor elétrico, bomba de água, conectores etc.;

▲ OEM rápido/design personalizado (1 mês);

▲ Controle preciso de temperatura (0.5 Você.C);

Ao longo do passado 10 anos, O TKT HVAC se desenvolveu rapidamente e se tornou o topo 3 Fabricantes de sistemas de gerenciamento térmico da bateria na China. Com rica experiência OEM, Cooperamos com muitos fabricantes de veículos mundialmente famosos. Como byd, TATA motos, Mudar de mobilidade, Daewoo, etc.. Os projetos cooperativos incluem uma variedade de sistema de gerenciamento térmico de bateria de barramento elétrico, Sistema de gerenciamento térmico da bateria de caminhão leve, Sistema de gerenciamento térmico da bateria de caminhão pesado, etc..

“Estudo de caso de gerenciamento térmico da bateria EV - uma história personalizada para a fortuna 500” Clique para ler (altamente recomendado)

Teste de veículo real, operação estável (Clique na imagem para ampliar)

Bem-vindo a entrar em contato conosco para aconselhamento de modelo profissional. Além disso, TKT Fornece serviços de personalização OEM, e os fabricantes de veículos podem consultar.

| Apoiar Personalizado Serviços |

|

|

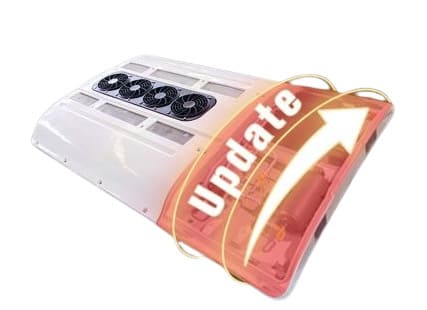

| Capacidade | Resfriamento: 8-10KW Aquecimento: 6-10KW (Opcional) |

Resfriamento: 5-6KW Aquecimento: 3KW (Opcional) |

| Aplicativo | 11-12M Ônibus Elétrico BTMS (DC240V-DC750V) |

8-10M Ônibus Elétrico BTMS (DC240V-DC750V) |

| Produto Modelo |

10R / 10CW para EBI Veja a página 10R/10CW |

5R / 5CW para EBI Veja a página 5R/5CW |

| Apoiar Personalizado Serviços |

|

|

| Capacidade | Resfriamento: 3-4KW Aquecimento: 1-2KW (Opcional) |

Resfriamento: 5-6KW Aquecimento: 3KW (Opcional) |

| Aplicativo | 6-7M Ônibus Elétrico BTMS (DC240V-DC750V) |

Caminhão Elétrico BTMS (DC240V-DC750V) |

| Produto Modelo |

3R / 3CW para EBI Veja a página 3R/3CW |

5CW para eruck Veja a página 5CW |

| Apoiar Personalizado Serviços |

|

|

| Capacidade | Resfriamento: 3-4KW Aquecimento: 1-2KW (Opcional) |

Resfriamento do BTMS: 8KW Bus A/C Refriamento: 143K BTUs |

| Aplicativo | Equipamento E-Pesado BTMS (DC240V-DC750V) |

E-bus a/c + BTMS (DC240V-DC750V) |

| Produto Modelo |

3R para EHE Veja a página 3R |

Exibir o sistema integrado da página |

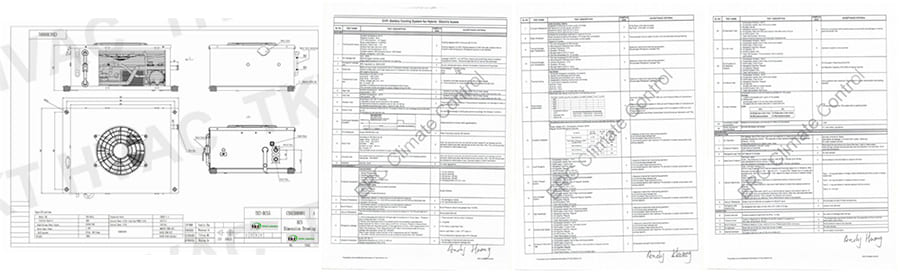

Contate-nos para imagens em alta resolução

1. Tipo de bateria e especificações: Diferentes cenários de aplicação de bateria têm requisitos diferentes para o sistema de gerenciamento térmico da bateria. Por exemplo, Se for uma bateria de energia e aplicada a um ônibus elétrico, Sua tensão de bateria é geralmente entre 280V-750V. Quando um ônibus elétrico está funcionando, A bateria produz muito calor, que requer um sistema de resfriamento de líquidos de bateria.

2. Espaço de reserva de EV: Quando diferentes fabricantes de veículos projetam veículos novos, O espaço de design de cada parte é planejado. Por exemplo, Porque caminhões elétricos têm caixas, Geralmente recomendamos projetar o sistema de gerenciamento térmico da bateria do caminhão (BTMS) do lado de fora do caminhão e adotando uma solução de instalação montada no lado. A vantagem disso é que é propício à liberação do desempenho de dissipação de calor e a eficiência de resfriamento da bateria é alta. Claro, Também temos outras soluções de resfriamento de bateria de caminhão que podem resolver 95% de necessidades de resfriamento por bateria de caminhão. Para outro exemplo, O espaço geral de máquinas elétricas pesadas é pequeno, Portanto, existem requisitos estritos no tamanho do sistema de gerenciamento térmico da bateria. Temos soluções de resfriamento de bateria divididas e também fornecemos serviços personalizados, Portanto, podemos resolver perfeitamente as necessidades do sistema de gerenciamento térmico da bateria de diferentes tamanhos.

3. Qualidade e confiabilidade: O sistema de gerenciamento térmico da bateria (BTMS) é muito importante para veículos elétricos. Ele pode não apenas garantir a segurança do veículo, mas também reduzir os custos operacionais do veículo. Um sistema de resfriamento de alta qualidade pode melhorar bastante a vida útil da bateria e o alcance do veículo, reduzindo assim os custos de substituição da bateria e os custos de cobrança de veículos. Portanto, é muito importante escolher um bom sistema de gerenciamento térmico da bateria. Os produtos TKT BTMS foram fornecidos à fortuna 500 empresas, passou suas inspeções estritas, e estão em operação real do veículo há mais de 5 anos. Somente a prática pode dizer se um produto é bom ou não. Cinco anos de operação estável é a melhor prova. O TKT tem rica experiência em cooperação com os fabricantes de veículos OEM, como Mundo do projeto, Projeto Tata Motors, Switch Mobility Project, etc..

Bobina condensadora, ventilador do condensador, tanque de água, bomba de água, permutador de calor, compressor elétrico, painel de controle, Módulo CAN, válvula de expansão, etc..

O sistema de condensador esfria o líquido de arrefecimento e a bomba de água passará o líquido de arrefecimento através do BTMS e o sistema de estrutura da bateria para liberar o calor gerado pela bateria.

O sistema de gerenciamento térmico da bateria é dividido principalmente em resfriamento de ar da bateria, refrigeração líquida da bateria, resfriamento de material de mudança de fase, e resfriamento de imersão em bateria. Diferentes métodos de resfriamento precisam ser selecionados com base no julgamento do cenário. Para veículos elétricos comerciais, Porque a capacidade da bateria dos veículos elétricos é relativamente grande, são todas baterias de alta tensão, Então eles liberam muito calor. Agora, o programa mais econômico e estável é o resfriamento líquido da bateria.

A função do sistema de gerenciamento térmico da bateria é ajustar a temperatura da bateria em tempo real e manter a bateria operando dentro da faixa de temperatura ideal para garantir o desempenho da bateria, vida e segurança. Principalmente falando, é dividido nas seguintes situações.

1. Evitar superaquecimento: Quando a temperatura da bateria é muito alta, O desempenho da bateria será afetado e pode até mesmo funcionar. O sistema de gerenciamento térmico da bateria pode reduzir a temperatura da bateria no tempo através da dissipação de calor e outros métodos para impedir que a bateria superaqueça.

2. Evite a sobrecorreramento: Em ambientes de baixa temperatura, O desempenho da bateria também será afetado e pode até não funcionar corretamente. O sistema de gerenciamento térmico da bateria pode aumentar imediatamente a temperatura da bateria por meio do aquecimento e outros métodos para impedir que a bateria sobrecunda.

3. Mantenha a estabilidade da temperatura da bateria: Durante a condução do veículo, A temperatura da bateria continuará a mudar. Se a flutuação da temperatura for muito grande, terá um impacto negativo no desempenho da bateria. O sistema de gerenciamento térmico da bateria pode manter a temperatura da bateria estável, controlando o fluxo do líquido de arrefecimento e outros métodos.

4. Melhorar a vida útil da bateria: Controlando a temperatura da bateria dentro da faixa ideal, a duração da bateria pode ser estendida. Reduza o número de substituições e reduza os custos de manutenção.

A tecnologia de refrigeração de baterias é mais exigente para o projeto de ônibus e caminhões elétricos, no qual a TKT vem trabalhando desde 2012.

A solução mais eficaz para melhorar a autonomia sem aumentar o número de baterias é um sistema de gerenciamento térmico de bateria personalizado.

Caixa de gerenciamento térmico de bateria EV – Personalizado para Fortune 500. O BTMS da TKT tem 10 anos de experiência em design.