Carregadores EV

Sistema de gerenciamento térmico de bateria

Ar condicionado elétrico

Ar condicionado acionado por motor

TKT HVAC é o fabricante de ar condicionado de barramento superior na China. É também o fornecedor de ar condicionado de barramento de BYD e TATA, que são o topo 500 empresas.

✲ Preço de fábrica, Alta qualidade!!

✲ Certificações: ISO 9001, IATF 16949, etc..

Aplicativo: AC para ônibus elétrico, Ônibus a diesel, Treinador, Van, etc..

TKT HVAC é o topo 3 Fabricantes de ar condicionado de ônibus e fornecedores de CA de ônibus na China. O TKT possui uma variedade de soluções de ar condicionado que podem ser aplicadas a ônibus elétricos, ônibus a diesel, Ônibus de transferência, ônibus escolares, treinadores, traslos do aeroporto, etc.. Nossas soluções podem atender 99% de necessidades do cliente, ao mesmo tempo em que fornece serviços personalizados mais profissionais. Como fabricantes de Bus CA estabelecidos para mais de 20 anos, Temos nossa própria fábrica na Índia, Nós também somos um famoso bus air conditioner manufacturers in India.

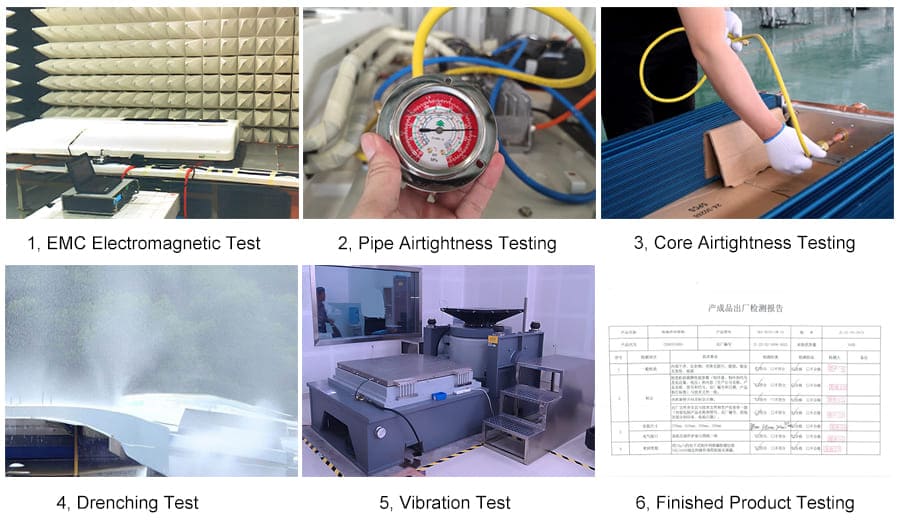

O ar condicionado de barramento é dividido principalmente em dois tipos, um é ar condicionado para ônibus elétrico E o outro é ar condicionado de barramento diesel. O ar condicionado para barramento elétrico é adequado apenas para ônibus elétrico puro e é alimentado por baterias elétricas. Este tipo de ar condicionado requer uma tensão muito alta, Geralmente entre 280-750V.

O ar condicionado para barramento diesel é adequado para ônibus a diesel tradicional e é impulsionado principalmente pelo motor. Este tipo de ar condicionado não poderá operar o ar condicionado quando o ônibus for interrompido. Claro, TKT tem Sub Motor Bus Ar Condicionado Para resolver esse problema e garantir que os ônibus a diesel tenham ar condicionado ininterrupto quando estacionados.

TKT suporta serviços OEM/ODM. Bem -vindo à consulta.

Como um fabricante veterano de ar condicionado para ônibus, temos plena consciência de que você recebe o que pagou. A TKT utiliza componentes de qualidade para garantir que nossos produtos tenham desempenho superior e vida útil mais longa. Quando você escolhe TKT Busthermo, você está obtendo um confiável, solução de refrigeração de última geração.

✔ Patente Design do sistema para garantir o super resfriamento para o clima tropical;

✔ Tubo de cobre parafuso interno & Alu hidrofílico. Para garantir 12-18 Anos de vida;

✔ Adotando componentes mundiais da marca para reduzir o custo do ciclo de vida;

✔ Instalação fácil, Operação & Serviço;

✔ Ar fresco disponível;

✔ OEM/sistema personalizado/mais requisito aceitável;

Saiba mais vantagens de barramento em detalhes

Como um dos principais fabricantes de ar condicionado de ônibus na China, A TKT Busthermo forneceu a Byd, Motores TATA, Marco Polo, Ônibus Yutong, Isuzu, Daewoo, Ônibus Fono BEIQI, e outros fabricantes de veículos globais.. Os produtos de ar condicionado passaram pela estrita inspeção de qualidade do topo do mundo 500 empresas.

Clique para mais casos (Carregar imagens HD, Espere pacientemente)

| Clique na imagem para ampliar |  |

|

| Resfriamento Capacidade |

42KW (143K BTUs) Aquecimento opcional |

55KW (187K BTUs) Aquecimento opcional |

| Aplicativo | 10M-12M E-Bus DC280-750V | Barramento de duplo decker dc450-750v |

| Produto Modelo |

420E Veja a página 420E |

550Ed Veja a página 550ed |

| Clique na imagem para ampliar |  |

|

| Resfriamento Capacidade |

16 KW (54K BTUs) Aquecimento opcional |

26 KW (88K BTUs) Aquecimento opcional |

| Aplicativo | 6M-7M E-Bus DC280-750V | 9M-10M E-Bus DC450-750V |

| Produto Modelo |

160E Veja a página 160E |

260E Visualize a página 260E |

Aplicativo: AC para ônibus diesel, Barramento elétrico, Treinador, Van, etc.. Contate-nos para aconselhamento de modelo profissional.

| Clique na imagem para ampliar |  |

|

| Resfriamento Capacidade |

40 KW (136K BTUs) Aquecimento opcional |

38 KW (129K BTUs) Aquecimento opcional |

| Aplicativo | 13M-14M Bus diesel | 12M-13M Bus diesel |

| Produto Modelo |

400B Veja a página 400b |

380B Exibir página 380b |

| Clique na imagem para ampliar |  |

|

| Resfriamento Capacidade |

34 KW (115K BTUs) Aquecimento opcional |

26 KW (88K BTUs) Aquecimento opcional |

| Aplicativo | 11Ônibus diesel M-12M | 9M-10M Bus diesel |

| Produto Modelo |

340B Veja a página 340b |

260M Veja a página 260m |

| Clique na imagem para ampliar |  |

|

| Resfriamento Capacidade |

20 KW (68K BTUs) Aquecimento opcional |

18 KW (61K BTUs) Aquecimento opcional |

| Aplicativo | 7M-8M Bus a diesel | 6M-7M Bus a diesel |

| Produto Modelo |

200M Veja a página 200m |

180M Veja a página 180m |

| Clique na imagem para ampliar |  |

|

| Resfriamento Capacidade |

14 KW (47K BTUs) Aquecimento opcional |

12 KW (40K BTUs) Aquecimento opcional |

| Aplicativo | Assentos<28 Van | Assentos<18 Van |

| Produto Modelo |

140V Veja a página 140V |

120V Veja a página 120V |

| Clique na imagem para ampliar |  |

|

| Resfriamento Capacidade |

5 KW (17K BTUs) |

16~ 55 kW (54~ 187K BTU) Aquecimento opcional |

| Aplicativo | Mini ônibus | E-bus puro |

| Produto Modelo |

50É Veja a página 50er |

160E ~ 550ed Exibir página de barramento elétrico AC |

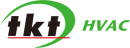

Teste eletromagnético EMC, Testes de aeroportação de tubos, Testes de herbeira central, Teste de encharcado, Teste de vibração, Teste acabado de produto. (Clique aqui para visualizar detalhes de inspeção da qualidade do ar condicionado do ar condicionado)

Temos muitos parceiros íntimos em todo o mundo. Você pode vir à nossa fábrica de TKT para inspeção no local e estabelecer um relacionamento cooperativo próximo conosco para alcançar uma situação em que todos saem ganhando. E trabalhar juntos para o desenvolvimento sustentável e proteção ambiental do mundo. (Clique para saber mais benefícios)

1. Por que nos escolher?

A. Qualidade confiável e preço competitivo

B: Vendas profissionais e bem treinadas, e suporte técnico

C: Condições de pagamento flexíveis

2. Qual é a sua política de garantia?

Primeiramente, nós fornecemos 18 meses de garantia a partir da data de entrega. Peças sobressalentes gratuitas serão fornecidas se as peças apresentarem defeito por motivos de qualidade durante o período de garantia. Mas os vídeos e a descrição da falha serão necessários para que o engenheiro verifique primeiro! Danos ou defeitos causados por uso indevido não cobertos pela garantia.

A TKT HVAC foi fundada em 1998. Até aqui, obteve muitos certificados de qualidade, como ISO9001:2015, IATF16969:2016, CE, EMI/EMC, etc.. E possui mais de 100 patentes relacionadas.

Tipicamente 7-10 dias se estiver em estoque.

Se não houver estoque, geralmente está em 3 semanas. Claro, a situação específica depende da quantidade do pedido e da tarefa de nossa fábrica.

O ar condicionado de barramento é um sistema de ar condicionado usado no barramento. Ele fornece um ambiente de viagem confortável para os passageiros, regulando a temperatura do ar, umidade e vazão. Um sistema de ar condicionado de ônibus consiste em componentes importantes, como o compressor, condensador, evaporador, válvula de expansão e ventilador. O compressor é responsável por comprimir o refrigerante e aumentar sua temperatura e pressão; O condensador dissipa a alta temperatura e refrigerante de pressão através do radiador, resfriá-lo e condensá-lo em um líquido de alta pressão; A válvula de expansão controla a taxa de fluxo e a pressão do refrigerante para que ele entre no evaporador; e o ventilador é usado para circular o ar e aumentar a taxa de fluxo de ar.

O processo de operação do sistema de ar condicionado de barramento é o seguinte: O compressor desenha o gás refrigerante de baixa temperatura e baixa pressão e o converte em um gás de alta temperatura e alta pressão através da compressão; posteriormente, A alta temperatura e o gás de alta pressão passa pelo condensador para dissipar o calor, e condensa em um líquido de alta pressão através do resfriamento; O líquido de alta pressão entra no evaporador através da válvula de expansão, e o líquido de baixa pressão no evaporador flui através do oleoduto, e o contato com o ar externo ocorre com a transferência de calor, e o refrigerante absorve o calor e evapora em um gás, fazendo a temperatura interna do evaporador subir. O refrigerante absorve o calor e evapora em gás, que diminui a temperatura dentro do evaporador, alcançando assim o efeito de resfriamento.

O ar condicionado de ônibus é aplicável a uma ampla gama de tipos de veículos, E a necessidade de instalar um sistema de ar condicionado é determinada principalmente por seu uso, Capacidade de transporte de passageiros e ambiente operacional.

Ônibus da cidade: Como o principal modo de transporte público nas cidades, Os ônibus da cidade geralmente precisam carregar um grande número de passageiros. A instalação de sistemas de ar condicionado nesses veículos pode garantir que os passageiros possam desfrutar de um ambiente de viagem confortável, mesmo nos meses quentes de verão.

Ônibus de longa distância: Os ônibus de longa distância geralmente são obrigados a viajar em rodovias ou rotas inter-regionais, onde os passageiros precisam passar longos períodos de tempo no veículo. Portanto, É necessário instalar sistemas de ar condicionado para ônibus de longa distância.

Ônibus turísticos: Os ônibus turísticos são usados principalmente para passeios turísticos e geralmente carregam turistas em longas viagens. A instalação de sistemas de ar condicionado de alta qualidade nesses veículos pode melhorar a experiência de viagem.

Ônibus de dois andares: Devido ao seu design especial e grande capacidade de passageiros, Os ônibus de dois andares requerem um sistema de ar condicionado que pode distribuir uniformemente o ar frio e fornecer um ambiente confortável.

Em geral, Os sistemas de ar condicionado de ônibus são adequados para modelos que precisam transportar um grande número de passageiros e correr por longas horas. Esses sistemas podem ser personalizados e otimizados para atender às necessidades específicas de diferentes modelos para garantir o conforto e a satisfação dos passageiros.

O refrigerante usado no ar condicionado de barramento, R-134A, é um dos refrigerantes mais comuns e amplamente utilizados.

R-134A agora é reconhecido internacionalmente como o principal cavalo de trabalho refrigerante substituindo o R-12, e é usado não apenas no ar condicionado de barramento, mas também em uma ampla gama de sistemas de refrigeração comercial e industrial.

R-407C é o refrigerante de escolha para ar condicionado em barramento elétrico. Além disso, Refrigerantes como R-22 e R-410A podem ser usados em algumas aplicações específicas ou no sistema de ar condicionado de barramento de fabricantes específicos.

1. Verifique a tubulação de ar condicionado e peças de conexão: Após uso prolongado, A tubulação de ar condicionado e peças de conexão podem ficar soltas ou rachadas, resultando em um efeito de resfriamento ruim. Portanto, é necessário verificar o status dessas peças regularmente.

2. Verifique a pressão do refrigerante: Refrigerante é o componente central do processo de resfriamento do ar condicionado. Use uma ferramenta de verificação de pressão de refrigerante para verificar a pressão do refrigerante e determinar se a pressão é normal com base nos valores padrão fornecidos pelo fabricante.

3. Limpe o evaporador e condensador: A limpeza desses componentes afeta diretamente o efeito de resfriamento. As superfícies do evaporador e condensador devem ser limpas regularmente para garantir que eles se dissipem bem.

4. Verifique o compressor e o ventilador: Verifique regularmente a qualidade do compressor e do ventilador. Eles afetarão o efeito de refrigeração.

Os ar condicionados de barramento TKT são usados em uma ampla gama de cenários, incluindo ar condicionado de ônibus escolar, ar condicionado de barramento de transportadora, ar condicionado de bus denso, ar condicionado de barramento de ônibus, ar condicionado tata ônibus, 24v ar condicionado de barramento, etc..

Ele apresenta em detalhes as partes principais do ar condicionado do ônibus e o princípio de funcionamento da parte principal. Fácil de entender e muito profissional.

A TKT possui diversas soluções em unidades de ar condicionado para ônibus. Este artigo apresenta muitos conhecimentos básicos e etapas de instalação do barramento A/C.

O projeto do chiller combinado AC é um design inovador que integra sistema de resfriamento de bateria EV e ar condicionado de ônibus elétrico.