Обзор управления температурным режимом батареи

Система управления температурным режимом аккумуляторной батареи поддерживает температуру аккумуляторной батареи электромобиля в нужном диапазоне, чтобы обеспечить больший запас хода и продлить срок службы батареи.. Мы также называем это батареей BTMS, охладителем батареи или системой охлаждения аккумуляторной батареи..

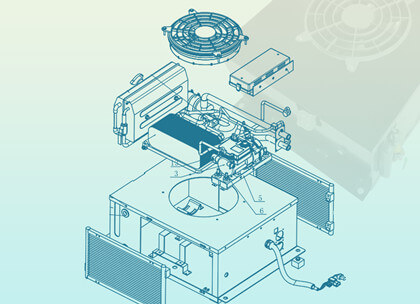

TKT Busthermo специализируется на разработке систем терморегулирования аккумуляторов электробусов., аккумуляторы для электрических грузовиков, аккумуляторы для электрических лодок и аккумуляторы для тяжелой электротехники. С охлаждающей/нагревательной мощностью 3–10 кВт., они поддерживают температуру силового аккумуляторного блока в оптимальном диапазоне за счет охлаждения охлаждающей жидкости и нагрева PTC.. Это позволяет электромобилям увеличить запас хода и срок службы..

Преимущества управления температурой батареи TKT

Теперь все больше и больше мировых лидеров 500 автопроизводители выбирают систему TKT BTMS, например БИД, Тата Моторс, Переключить мобильность, КОТ Гусеница и многие другие. В основном из-за нас:

1. Продукты BTMS имеют хорошее качество и прошли рыночные испытания на 10 годы.

2. Точный контроль температуры (0.5℃), легкий вес, и т. д..

3. Справедливая и привлекательная цена.

4. Кроме того, Это деталь с широкими возможностями настройки, и мы можем изготовить ее в точном соответствии со спецификациями клиента.. Охлаждение, обогрев, размеры, и многое другое, все можно настроить.

Решение для управления температурным режимом батареи

Существует множество видов продукции ТКТ.. Добро пожаловать в связаться с нами для консультации специалиста или Электронная почта:md@tkt-hvac.com.

Система охлаждения аккумуляторной батареи Похожие новости

“Удача 500 Проект системы управления температурным режимом аккумуляторной батареи грузовика TATA” Нажмите, чтобы прочитать

“Управление температурой аккумулятора в центре внимания грузовиков & Автобус и т. д.. – Зрелые передовые решения” Нажмите, чтобы прочитать (настоятельно рекомендуется)

“Решения по настройке управления температурным режимом батареи и общие направления настройки” Нажмите, чтобы прочитать

Важные партнеры по управлению температурой батареи

Научные знания по управлению температурным режимом батареи

Что такое система терморегулирования аккумулятора?

Система терморегулирования аккумулятора (БТМС) представляет собой замкнутую систему регулирования температуры, состоящую из теплопроводящей среды, блок измерения и контроля, и оборудование для контроля температуры. Это позволяет силовой батарее работать в соответствующем температурном диапазоне, чтобы поддерживать наилучшее состояние использования и обеспечивать производительность и срок службы аккумуляторной системы..

Обзор управления температурой аккумуляторов в электромобилях (важность)

Силовая батарея является единственным источником энергии для электромобилей и важным показателем, влияющим на производительность электромобилей.. Это будет сопровождать определенное тепло во время процесса зарядки и разрядки., что приведет к повышению температуры, а повышение температуры повлияет на многие параметры рабочих характеристик аккумулятора., например, внутреннее сопротивление, Напряжение, СОЦ, доступная мощность, эффективность зарядки и разрядки, и срок службы батареи.

Проблема теплового воздействия аккумуляторной батареи повлияет на производительность и срок службы автомобиля.. Поэтому, управление температурой аккумулятора очень важно для производительности и срока службы аккумулятора, а также пробега автомобиля..

Какие существуют типы систем терморегулирования аккумуляторов? (БТМС) ?

В настоящий момент, в основном делится на воздушное охлаждение, жидкостное охлаждение, Охлаждение материала с фазовым переходом и иммерсионное охлаждение. Для системы охлаждения аккумулятора электромобиля, жидкостное охлаждение — наиболее распространенное и стабильное решение.

Жидкостное охлаждение аккумулятора: Аккумулятор обменивается теплом с охлаждающей жидкостью через охлаждающую пластину.. Охлажденный или нагретый теплоноситель подается в теплообменник водяным насосом., а внутри него осуществляется теплообмен и шунтирование, таким образом формируется непрерывная и стабильная система жидкостного охлаждения аккумулятора.. Благотворный цикл.

Воздушное охлаждение аккумулятора: В основном используется принцип конвекции воздуха для циркуляции воздуха в аккумуляторном отсеке.. Циркулирующий воздух отводит тепло от аккумулятора., тем самым снижая температуру аккумулятора. Недостатком является то, что эффективность охлаждения относительно низкая., особенно в условиях высоких температур.

Материал для изменения фазы батареи (ПКМ) охлаждение: Материалы ПКМ в основном используются для превращения твердого тела в жидкость при определенных температурах окружающей среды., тем самым реализуя функции рассеивания тепла и нагрева батареи.. Недостатками являются относительно низкая эффективность охлаждения и необходимость регулярной замены материалов фазового перехода..

Иммерсионное охлаждение аккумулятора: Поместив батарею непосредственно в специальную охлаждающую жидкость., эффекты конвекции и проводимости жидкости используются для быстрой передачи тепла, выделяемого аккумулятором, охлаждающей жидкости, тем самым достигается охлаждающий эффект аккумулятора. Недостатками являются более высокие требования к теплоносителю и большие последующие затраты на техническое обслуживание..

Как работает терморегулирование батареи?

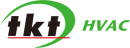

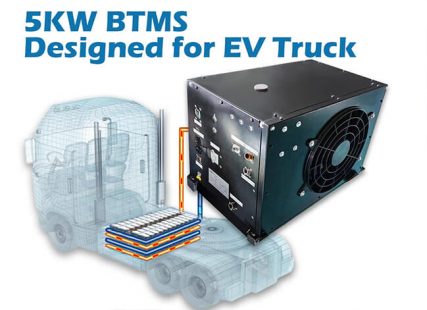

Система жидкостного охлаждения аккумулятора состоит из компрессора., конденсатор, расширительный клапан, пластинчатый теплообменник, электронный водяной насос, Жидкостный нагреватель PTC, расширительный бачок, и электрическое управление. Когда батарею необходимо охладить для работы, аккумулятор обменивается теплом с охлаждающей жидкостью через охлаждающую пластину, а нагретая охлаждающая жидкость подается в теплообменник электронным водяным насосом.. Хладагент подается в одну сторону теплообменника, а охлаждающая жидкость – в другую сторону.. Оба обмениваются теплом в теплообменнике., чтобы тепло отводилось хладагентом. Холодная охлаждающая жидкость вытекает из теплообменника и затем попадает в аккумулятор.. Система образует цикл; когда аккумулятор имеет низкую температуру и его необходимо нагреть, контур охлаждения закрывается и включается жидкостный нагреватель PTC. Охлаждающая жидкость нагревается и направляется в аккумулятор., и батарея нагревается через охлаждающую пластину. Система управления температурой батареи контролирует внутреннюю температуру батареи, управляя включением и выключением холодильного контура и жидкостного нагревателя PTC..

В чем разница между BMS и BTMS?

Проще говоря, BMS — это система управления батареями., который включает в себя более широкий спектр. BTMS — это система управления температурным режимом аккумулятора, являющаяся частью BMS.. Для автоматизированной работы BTMS требуются инструкции от BMS.. Его можно понимать как взаимосвязь между мозгом и конечностями..

Другие часто используемые выражения

аккумулятор с водяным охлаждением, аккумуляторная батарея с жидкостным охлаждением, терморегулирование аккумуляторов, система охлаждения аккумуляторной батареи, блок охлаждения аккумулятора, система управления температурой аккумулятора btms, система охлаждения литиевой батареи, охлаждающий литий-ионный аккумулятор, управление температурой литий-ионного аккумулятора, система управления температурой аккумулятора, охлаждение литиевой батареи, система управления температурой аккумулятора для электромобилей, терморегулирование аккумулятора, система охлаждения аккумулятора в электромобиле, системы охлаждения аккумуляторов электромобилей, система управления температурой аккумулятора автомобиля, система охлаждения аккумулятора электромобиля, система охлаждения аккумулятора электромобиля, система охлаждения высоковольтной батареи, термоуправление аккумулятором, система управления температурой аккумулятора EV, управление температурой аккумуляторной батареи, аккумулятор жидкостного охлаждения.