With the gradual deterioration of the greenhouse effect, the development of clean energy has been the focus of environmental protection over the years. As the most important mobility tool for human beings, the electrification of automobiles is an inevitable trend. Electric vehicles use high-voltage batteries as a power source to replace traditional fuels, thus reducing environmental pollution. If batteries are used as a power source, then two obvious problems of batteries need to be solved. These two problems are the huge heat generated during discharge and the inefficiency at low temperatures. What is battery thermal management system? It is the cooling/heating method to keep the battery of an electric vehicle within the appropriate temperature range, so as to release the battery energy stably and efficiently. This is one of the important aspects to optimize the driving range and safety of electric vehicles.

Customized Battery Thermal Management System for TATA Motors

The system has been running stably for 5 years.

The full name of BMS is Battery Management System. With the development of BMS, now it has many functions, such as battery parameter monitoring, battery status estimation, online fault diagnosis, charge control, automatic equalization, thermal management, etc.

BTMS is Battery Thermal Management System, which enables the power battery to operate within the appropriate temperature range to ensure the performance and life of the battery system.BTMS is a subsystem of BMS, focusing on the thermal management function of the battery.

Battery liquid cooling system is now the most mature solution for electric vehicles. It is a must-have system for any electric vehicle in any region.

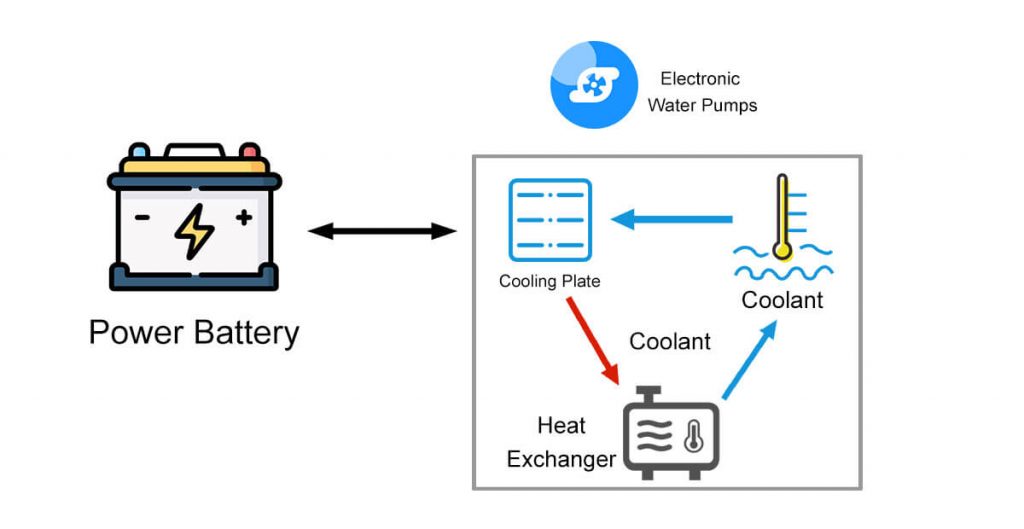

First, the battery liquid cooling system circulates coolant through the lines by means of an electronic water pump. The cold coolant flows to the cooling plates, which then take away a lot of the heat from the battery.

The cooling plate is specifically designed for battery cooling. It fits closely to the battery pack and completes the heat exchange between the coolant and the battery.

Next, the battery liquid cooling system then passes through the compressor, heat exchanger and so on, to complete the circulation cooling of the coolant.

The common coolant is usually water or glycol solution.

Under the joint action of these two cycles, the battery cooling system efficiently and stably takes away the heat of the power battery.

Battery heating systems are only used in regions and countries with very cold climates. It is an optional solution.TKT HVAC's battery thermal management system is accomplished by PTC heating.

PTC heater is composed of PTC ceramic heating element and aluminum tube, which has the advantages of small thermal resistance and high heat exchange efficiency, and it is a kind of electric heater with automatic constant temperature and power saving.

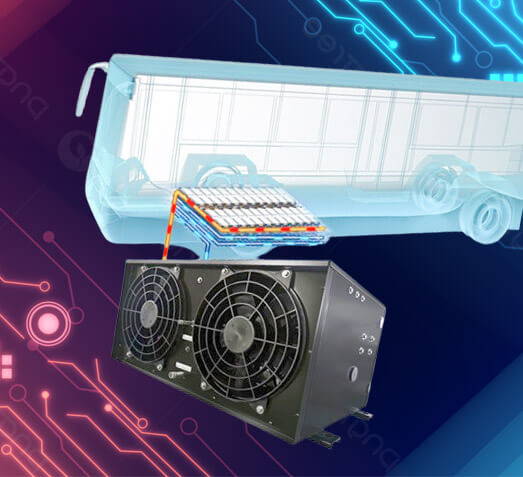

Electric bus battery cooling system is a battery thermal management system used in electric buses. It has stringent cooling requirements because of the high energy of the power cells in battery buses. It is usually installed on the roof of the electric bus.

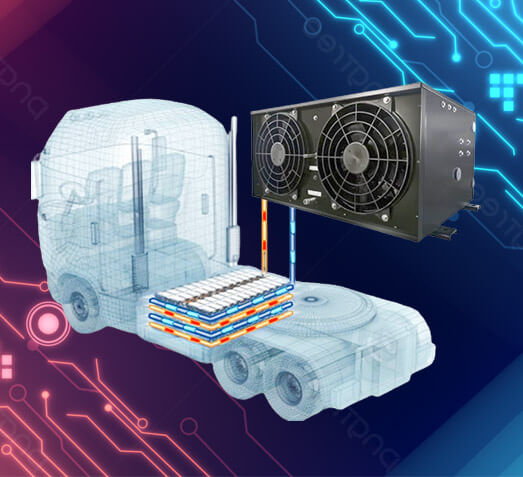

Electric truck battery thermal management system is a battery cooling system installed on an electric truck. It is usually installed on the side of the electric truck. This is conducive to the fan blowing to accelerate heat dissipation.

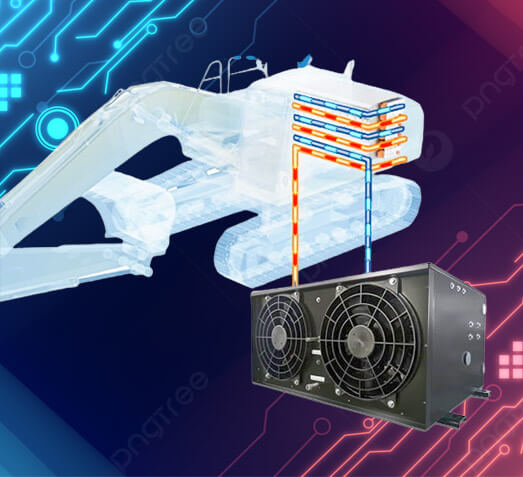

Battery cooling system for electric heavy equipment includes many types. For example, electric excavators, electric yachts, electric dump trucks, etc. Their characteristics are that the power demand is relatively large.

Email: md@tkt-hvac.com

WhatsApp: +86 13015505615

Facebook: https://www.facebook.com/TKTHVAC/

linkedin: https://www.linkedin.com/company/tkt-hvac

YouTube: https://www.youtube.com/@TKTHVAC